Overview of 45° Elbow

Key Features of 45° Elbow

Optimized Flow Efficiency

Material Versatility and Compatibility

Space-Saving Design Configuration

Robust Construction and Durability

Installation Flexibility and Compatibility

Typical Applications of 45° Elbow

Industrial Process Piping

HVAC and Mechanical Systems

Water Supply and Distribution Networks

Oil and Gas Pipelines

Power Generation Facilities

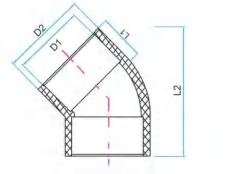

Technical Specifications

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SIZE | NO. | D1 | D2 | L1 | L2 |

| DN15 | XW15 | 20.3 | 26.3 | 16.5 | 47.36 |

| DN20 | XW20 | 25.3 | 31.9 | 19 | 55.18 |

| DN25 | XW25 | 32.35 | 39.95 | 22.5 | 66.79 |

| DN32 | XW32 | 40.4 | 49.8 | 26.5 | 79.65 |

| DN40 | XW40 | 50.45 | 60.25 | 31.5 | 95.83 |

| DN50 | XW50 | 63.5 | 75.9 | 38 | 116.16 |

| DN65 | XW65 | 75.5 | 88.91 | 44 | 141.61 |

| DN80 | XW80 | 90.55 | 105.15 | 51.5 | 166.39 |

| DN100 | XW100 | 110.6 | 127.39 | 61.5 | 197.19 |

| DN125 | XW125 | 140.6 | 161.4 | 76 | 248.87 |

| DN150 | XW150 | 160.7 | 184.5 | 86.5 | 280.95 |

| dn200 | XW200 | 200 | 228.1 | 106.2 | 344.5 |

| DN200 | XW200 | 226.2 | 253.8 | 118.5 | 389.7 |

| dn250 | XW250 | 250 | 283.4 | 131.5 | 424 |

| DN250 | XW250 | 281.5 | 315.5 | 147 | 465 |

| DN300 | XW300 | 316.7 | 355 | 165 | 538 |

| DN350 | XW350 | 356.8 | 395 | 185 | 600 |

| DN400 | XW400 | 402 | 442 | 208 | 660 |

| DN250 (PN10) | XW250 | 280.6 | 306 | 147 | 440 |

| DN300 (PN10) | XW300 | 315.7 | 344 | 165 | 495 |

| DN350 (PN10) | XW350 | 355.8 | 385 | 183.5 | 558 |

| DN400 (PN10) | XW400 | 401 | 432 | 208 | 620 |