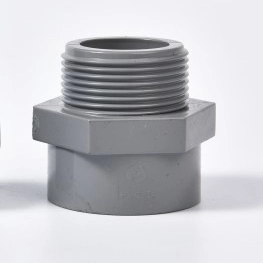

Introduction of CPVC Pipeline

Features of CPVC Pipeline

- Enhanced Heat Resistance – Withstands continuous temperatures up to 95°C and Vicat softening points of 100–125°C, ideal for hot water and industrial thermal fluids.

- Exceptional Chemical Resistance – Highly resistant to acids, alkalis, salts, and oxidizers, making it suitable for chemical plants, electroplating facilities, and wastewater treatment.

- Flame Retardancy – Oxygen index of ≥60%, ensuring self-extinguishing properties and compliance with fire safety standards.

- Lightweight & Easy Installation – Simple solvent-cement jointing reduces labor costs and accelerates project completion.

- Hygienic & Non-Toxic – Certified for potable water safety (e.g., NSF/GB 17219), preventing bacterial growth and ensuring water purity.

- Long-Term Durability – Resists UV exposure, scaling, and corrosion, maintaining performance under pressures up to 6 MPa for decades.

Typical Uses of CPVC Pipeline

- Industrial Hot Water & Chemical Transport – For corrosive fluid handling in chemical, pharmaceutical, and metal processing plants

- Fire Sprinkler Systems – Certified for fire protection pipelines due to high-temperature stability and flame retardancy.

- Potable Water Distribution – Safe for hot and cold water supply in residential, commercial, and healthcare facilities.

- Ultrapure Water & Electronics – Used in semiconductor and pharmaceutical industries where water purity is critical.

Technical Specifications

-

Sizes: DN20–DN800 -

Pressure Ratings: 1.0–1.6 MPa (customizable to SDR11-SDR40) -

Standards: ASTM D2846, GB/T 18993.1, ISO 15494 -

Certifications: SGS/CE, NSF compliant

FAQs of Sikerui CPVC Pipeline

Q1: Can your company customize products?

A: Yes, Sikerui Pipe is a leading supplier of CPVC piping systems. We work closely with clients to provide tailored solutions, offering customization in dimensions (from DN15 to DN600), pressure ratings, and specific application requirements for various industrial and construction needs.

Q2: How can I get a sample to check quality?

A: We can provide sample sections of our CPVC pipes for quality evaluation. Samples are typically prepared within one week after specifications are agreed upon, allowing you to verify material quality and performance characteristics .

Q3: What about your delivery time? Can we receive our goods on time?

A: Our standard delivery time is approximately 2-3 weeks after order confirmation. The exact timeline depends on the order quantity and product specifications. Common standard sizes are often available for quicker dispatch.

Q4: What is the guarantee for your products? How are quality complaints resolved?

A: We ensure strict quality control in line with national standards for CPVC pipe products . Should any quality concerns arise, you can provide detailed documentation (e.g., photos, test data). Our quality tracking system ensures prompt feedback. If an issue is confirmed, we will arrange for replacement or refund as appropriate.

Q5: What are your terms of payment?

A: We support various international trade terms including EXW, FOB, CIF, and DDU, offering flexibility to meet different global client needs.