Overview of Double Union Ball Valve

Key Features of Double Union Ball Valve

-

Easy Maintenance and Installation The double union design incorporates union nuts on both ends, allowing the valve to be detached without cutting pipes or dismantling adjacent components . This simplifies cleaning, inspection, and replacement, minimizing system downtime in critical operations such as water treatment plants or chemical processing units . -

Leak-Free Sealing and Durability Equipped with PTFE or EPDM seals and reinforced seats, the valve ensures bubble-tight shut-off, even under high-pressure fluctuations . The robust construction resists corrosion, abrasion, and chemical degradation, maintaining integrity in aggressive media like acids, alkalis, or slurries . -

Space-Saving and Versatile Design Its compact form factor reduces installation space by up to 30% compared to multi-valve assemblies, while the standardized unions support integration into existing systems without modification . The valve adapts to horizontal, vertical, or angled pipelines, with options for manual handles or automated actuators (pneumatic/electric) . -

High Flow Efficiency Full-port variants provide an unobstructed flow path that minimizes pressure drop and turbulence, ideal for applications requiring minimal flow resistance, such as irrigation or fire protection systems . Reduced-port versions offer cost savings for less demanding uses while maintaining reliable control . -

Broad Material Compatibility Materials like stainless steel 316 handle corrosive fluids, while PVC and brass variants suit water or low-temperature services . This versatility ensures compatibility with potable water, oils, gases, and chemicals, adhering to FDA, ISO, and NSF standards for safety .

Technical Specifications

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Typical Applications of Double Union Ball Valve

-

Water Treatment and Distribution: Used in municipal water systems and purification plants to isolate sections for maintenance, ensuring uninterrupted supply with leak-free performance . -

Chemical and Pharmaceutical Processing: Stainless steel valves handle aggressive chemicals like acids or solvents, providing corrosion resistance and easy sterilization for FDA-compliant operations . -

HVAC and Fire Protection Systems: Regulate water or coolant flow in heating/cooling circuits, with EPDM seals accommodating thermal cycling and pressure surges in commercial buildings . -

Oil, Gas, and Mining: Full-port valves manage crude oil, gases, or abrasive slurries, with reinforced designs resisting erosion in upstream and midstream pipelines . -

Agriculture and Irrigation: PVC valves distribute water or fertilizers in irrigation networks, leveraging UV resistance and durability for outdoor use .

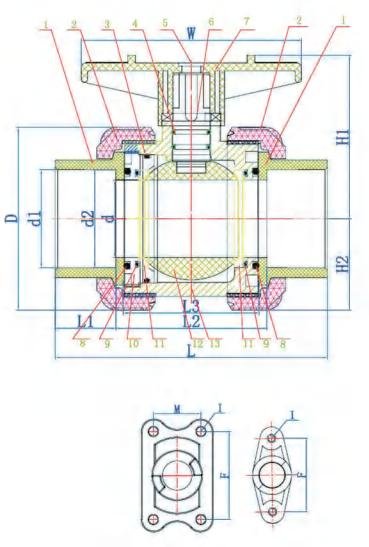

| Number | Name | Material | Quantity | Unit |

| 3/4/8/9 | O-Ring | EPDM/VITON | 7 | PCS |

| 01 | Socket/Socket End | UPVC/CPVC/PPH | 2 | PCS |

| 02 | Nut | UPVC/CPVC/PPH | 2 | PCS |

| 05 | Adapte/Connector | SUS304 | 1 | PCS |

| 06 | Rod/Bar | UPVC/CPVC/PPH | 1 | PCS |

| 07 | Bracket/Support | UPVC/SUS304 | 1 | PCS |

| Number | Name | Material | Quantity | Unit |

| 10 | Liner | UPVC/CPVC/PPH | 1 | PCS |

| 11 | Sealing Ring | PTFE | 2 | PCS |

| 12 | Ball | UPVC/CPVC/PPH | 1 | PCS |

| 13 | Body | UPVC/CPVC/PPH | 1 | PCS |

| 14 | Screw | SUS304 | 6-8 | PCS |

| 15 | Electric Actuator | SUS304 | 1 | PCS |

| SIZE | d | d1 | d2 | ||||||||

| ANSI | DIN | JIS | CNS | PPH | ANSI | DIN | JIS | CNS | PPH | ||

| 1/2″ (15) | 15 | 21. 40 | 20. 25 | 22. 30 | 22. 40 | 19. 30 | 21. 25 | 20. 05 | 21. 85 | 21. 90 | 19. 00 |

| 3/4″ (20) | 20 | 26. 75 | 25. 25 | 26. 30 | 26. 40 | 24. 10 | 26. 58 | 25. 05 | 25. 85 | 25. 90 | 23. 80 |

| 1″ (25) | 25 | 33. 52 | 32. 25 | 32. 33 | 34. 50 | 31. 00 | 33. 28 | 32. 05 | 31. 85 | 33. 90 | 30. 70 |

| 1–1/4″ (32 | 32 | 42. 28 | 40. 25 | 38. 43 | 42. 50 | 39. 00 | 42. 05 | 40. 05 | 37. 85 | 41. 90 | 38. 60 |

| 1–1/2″ (40) | 40 | 48. 40 | 50. 25 | 48. 46 | 48. 60 | 49. 00 | 48. 12 | 50. 05 | 47. 75 | 47. 90 | 48. 60 |

| 2″ (50) | 50 | 60. 45 | 63. 25 | 60. 56 | 60. 60 | 61. 90 | 60. 18 | 63. 05 | 59. 75 | 59. 90 | 61. 40 |

| 2–1/2″ (65) | 63 | 73. 30 | 75. 25 | 76. 60 | 76. 70 | 73. 60 | 72. 85 | 75. 05 | 75. 87 | 75. 90 | 72. 30 |

| 3″ (80) | 75 | 89. 25 | 90. 35 | 89. 60 | 89. 70 | 88. 30 | 88. 70 | 90. 05 | 88. 83 | 88. 90 | 86. 90 |

| 4″ (100) | 90 | 114. 60 | 110. 35 | 114. 70 | 115. 00 | 108. 00 | 114. 10 | 110. 05 | 113. 98 | 113. 80 | 106. 40 |

| 规格(SIZE) | D | L | L1 | L2 | L3 | W | H1 | H2 | F | M | I | Operating torque(NM) |

| 1/2″(15) | 54.00 | 106.00 | 23.00 | 60.00 | 52.00 | 84.00 | 52.50 | 27.50 | 31.00 | – | M6 | 2.0 |

| 3/4″(20) | 63.00 | 114.00 | 26.00 | 62.00 | 54.00 | 90.00 | 59.00 | 32.00 | 33.00 | – | M6 | 2.5 |

| 1″(25) | 73.50 | 128.00 | 29.00 | 70.00 | 62.00 | 106.00 | 67.50 | 37.25 | 40.00 | – | M6 | 4.0 |

| 1-1/4″(32) | 84.50 | 144.00 | 33.00 | 78.00 | 70.00 | 116.00 | 77.50 | 42.75 | 52.00 | – | M8 | 5.0 |

| 1-1/2″(40) | 98.00 | 158.50 | 35.50 | 87.50 | 79.50 | 128.00 | 90.00 | 50.00 | 52.00 | – | M8 | 7.5 |

| 2″(50) | 118.00 | 172.00 | 38.50 | 95.00 | 85.00 | 140.00 | 106.00 | 60.00 | 70.00 | – | M8 | 8.5 |

| 2-1/2″(65) | 150.00 | 278.00 | 64.50 | 144.50 | 132.50 | 198.00 | 136.50 | 76.50 | 84.00 | 45.00 | M10 | 13 |

| 3″(80) | 169.00 | 310.00 | 70.00 | 166.00 | 150.00 | 218.00 | 149.50 | 86.00 | 84.00 | 45.00 | M10 | 16 |

| 4″(100) | 190.00 | 352.00 | 84.00 | 181.00 | 157.00 | 235.00 | 166.00 | 98.00 | 121.00 | 49.00 | M12 | 25 |