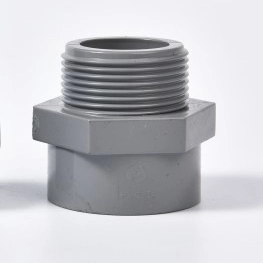

Product Overview

Features of CPVC Positive Cross Tube

-

Four-Way Flow Distribution -

Engineered with four uniform outlets to facilitate efficient multidirectional flow splitting or convergence, reducing turbulence and maintaining pressure balance in complex pipeline networks.

-

-

Superior Corrosion & Chemical Resistance -

Highly resistant to acids, alkalis, and corrosive fluids, ideal for industrial wastewater, chemical transport, and agricultural systems involving fertilizers or pesticides.

-

-

Smooth Interior Surface -

Precision-molded inner walls minimize friction loss, prevent sediment buildup, and ensure optimal flow efficiency for water, sewage, or chemical fluids.

-

-

Lightweight and Easy Installation -

Up to 50% lighter than metal equivalents, enabling quick solvent cement or threaded connections. Reduces labor time and transportation costs significantly.

-

-

Durable Under Pressure -

Rated for pressures up to PN16 (1.6 MPa) and temperatures from 0°C to 60°C. Robust SCH80 variants withstand higher stress for demanding industrial applications.

-

-

Eco-Friendly and Potable Water Safe -

Complies with drinking water standards (e.g., ISO 4422), featuring non-toxic, UV-resistant material suitable for freshwater systems.

-

Typical Uses of CPVC Positive Cross Tube

-

Water Distribution Systems Used in municipal and residential water supply networks to create balanced branch connections for fixtures, ensuring leak-free performance without corrosion risks. -

Industrial Chemical Processing Ideal for plants handling acids, alkalis, or abrasive fluids, where its chemical resistance enables safe multidirectional diversion of process streams. -

Agricultural Irrigation Facilitates efficient flow division in large-scale sprinkler or drip irrigation systems, resisting degradation from fertilizers and UV exposure. -

Mining and Drainage Effective in draining corrosive liquids or ventilating gases in mines, thanks to durability and ease of installation in confined spaces. -

Electrical Conduit Systems Provides insulated, four-way junction points for cable protection in electrical and telecommunications installations, safeguarding against moisture and physical damage.

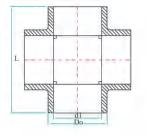

Range of Production

| SIZE | D0 | d1 | L |

| DN15 | 26.30 | 20.30 | 55.40 |

| DN20 | 31.90 | 25.30 | 65.40 |

| DN25 | 39.95 | 32.35 | 79.40 |

| DN32 | 49.80 | 40.40 | 95.40 |

| DN40 | 60.25 | 50.45 | 115.40 |

| DN50 | 75.90 | 63.50 | 141.40 |

| DN65 | 88.91 | 75.50 | 165.00 |

| DN80 | 105.15 | 90.55 | 195.00 |

| DN100 | 127.39 | 110.60 | 235.00 |

| DN125 | 161.40 | 140.60 | 296.00 |

| DN150 | 184.50 | 160.70 | 336.00 |

| DN200 | 253.80 | 226.20 | 465.00 |