Overview of Pipe Cap

Key Features of Pipe Cap

-

Superior Sealing Performance Pipe caps create leak-proof seals through precision-machined threads, welded joints, or compression fittings, effectively blocking moisture, dust, and contaminants from entering pipeline systems . This ensures the integrity of stored fluids or gases and prevents corrosion during downtime or testing phases . -

Corrosion and Chemical Resistance Constructed from materials such as stainless steel (304/316), PVC, and LDPE, pipe caps demonstrate exceptional resistance to acids, alkalis, and corrosive media, making them suitable for chemical processing, oil and gas, and water treatment applications . Special coatings like epoxy or galvanization further enhance durability in aggressive environments . -

High-Pressure and Temperature Tolerance Pipe caps withstand pressures up to 6,000 PSI and temperatures from -50°C to 400°C, depending on material and design . Butt-weld caps excel in high-pressure systems, while threaded variants offer reusable solutions for moderate conditions . -

Easy Installation and Reusability Lightweight designs allow for tool-free installation in many cases, with threaded and push-on caps enabling quick deployment or removal without specialized equipment . Reusable configurations reduce long-term maintenance costs and downtime . -

Versatile Material and Size Options Available in sizes from ½” to 48″ and materials including carbon steel, PVC, stainless steel, and HDPE, pipe caps adapt to specific operational needs, whether for high-temperature steam lines, potable water systems, or chemical transport . Customization supports non-standard diameters and shapes (e.g., oval, rectangular) . -

Environmental Protection and Safety Pipe caps act as barriers against environmental hazards, preventing accidental emissions of hazardous fluids and complying with safety regulations in industries like petroleum and pharmaceuticals . Their use in pressure testing ensures system reliability before commissioning .

Typical Applications of Pipe Cap

-

Pipeline Maintenance and Testing: Used to seal pipe ends during hydrostatic testing, system repairs, or temporary shutdowns, ensuring no contaminants enter the line and maintaining pressure integrity for safety checks . -

Chemical and Petrochemical Plants: Protect pipelines transporting acids, solvents, and hydrocarbons from corrosion and leakage, with stainless steel or alloy caps providing resilience in aggressive environments . -

Water and Wastewater Systems: PVC or HDPE caps serve in potable water distribution and drainage networks, preventing debris ingress and complying with health standards such as NSF/ANSI 61 . -

Oil and Gas Pipelines: Shield pipe ends from moisture, sulfur, and mechanical damage in upstream and midstream operations, with coatings like 3LPE enhancing longevity in sour service conditions . -

Construction and Plumbing: Secure exposed pipes during building projects, preventing accidental damage and ensuring cleanliness until system commissioning . -

Electrical Conduit Protection: Non-conductive PVC or LDPE caps safeguard conduit threads from moisture and dust, maintaining insulation integrity in electrical installations .

Technical Specifications

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

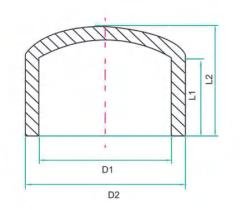

| SIZE | Number | D1 | D2 | L1 | L2 |

| DN15 | GD15 | 20.3 | 26.3 | 16.5 | 21.81 |

| DN20 | GD20 | 25.3 | 31.9 | 19 | 25.68 |

| DN25 | GD25 | 32.35 | 39.95 | 22.5 | 30.62 |

| DN32 | GD32 | 40.4 | 49.8 | 26.5 | 36.81 |

| DN40 | GD40 | 50.45 | 60.25 | 31.5 | 44.68 |

| DN50 | GD50 | 63.5 | 75.9 | 38 | 53.81 |

| DN65 | GD65 | 75.5 | 88.91 | 44 | 62.44 |

| DN80 | GD80 | 90.55 | 105.15 | 51.5 | 73.11 |

| DN100 | GD100 | 110.6 | 127.39 | 61.5 | 84.27 |

| DN125 | GD125 | 140.6 | 161.4 | 76 | 110.06 |

| DN150 | GD150 | 160.7 | 184.5 | 86.5 | 125.9 |

| dn200 | GD200 | 200 | 228.1 | 107.37 | 147 |

| DN200 | GD200 | 226.2 | 253.8 | 118.5 | 170.58 |

| dn250 | GD250 | 250 | 283.4 | 131.5 | 180 |

| DN250 | GD250 | 281.5 | 314.8 | 147 | 213 |

| DN300 | GD300 | 316.7 | 344.5 | 165 | 216 |

| DN350 | GD350 | 356.8 | 395 | 185 | 252 |

| DN400 | GD400 | 402 | 442 | 208 | 285 |

| DN350 (PN10) | GD350 | 356.8 | 386.2 | 183.5 | 255 |

| DN400 (PN10) | GD400 | 402 | 432.7 | 208 | 296 |