Overview of Pipe Clamps

Key Features of Pipe Clamps

Superior Load Capacity and Durability

Vibration Damping and Noise Reduction

Corrosion Resistance and Environmental Adaptation

Flexible Installation and Adjustability

Temperature Tolerance and Thermal Expansion Management

Typical Applications of Pipe Clamps

Industrial Process Piping

HVAC and Mechanical Systems

Plumbing and Water Supply Systems

Electrical and Conduit Installation

High-Rise Building Infrastructure

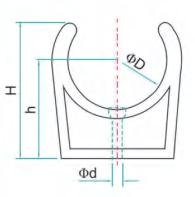

Technical Specifications

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SIZE | D | H | h | d |

| DN15 | 20.20 | 35.40 | 27.20 | 5.20 |

| DN20 | 25.10 | 41.00 | 30.50 | 5.20 |

| DN25 | 32.10 | 52.80 | 40.00 | 5.20 |

| DN32 | 40.10 | 59.30 | 44.00 | 5.20 |

| DN40 | 50.10 | 71.20 | 52.00 | 5.20 |

| DN50 | 63.10 | 88.50 | 65.00 | 5.20 |

| DN65 | 75.10 | 91.80 | 62.50 | 5.20 |

| DN80 | 90.10 | 103.90 | 69.00 | 5.20 |

| DN100 | 110.10 | 124.50 | 85.00 | 5.20 |

Frequently Asked Questions (FAQs)