Overview of Reducers

Key Features of Reducers

Flow Transition Efficiency

Material Versatility and Compatibility

Pressure Integrity and Structural Stability

Installation Flexibility

Types of Reducers and Their Applications

Concentric Reducers

Eccentric Reducers

Typical Applications of Reducers

Pump Suction and Discharge Lines

Pipeline Size Transition

Pipe Rack Installations

Process Equipment Connections

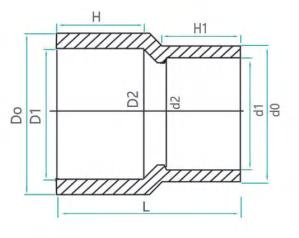

Technical Specifications

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SIZE | D1 | D2 | H | d1 | d2 | H1 | L |

| DN20X15 | 25.3 | 31.9 | 19 | 20.3 | 26.3 | 16.5 | 40 |

| DN25X15 | 32.35 | 39.5 | 22.5 | 20.3 | 26.3 | 16.5 | 47.8 |

| DN25X20 | 32.35 | 39.5 | 22.5 | 25.3 | 31.9 | 19 | 47.4 |

| DN32X20 | 40.4 | 49.8 | 26.5 | 25.3 | 31.9 | 19 | 56.6 |

| DN32X25 | 40.4 | 49.8 | 26.5 | 32.35 | 39.95 | 22.5 | 54.8 |

| DN40X15 | 50.45 | 62 | 31.5 | 20.3 | 27 | 16.5 | 66 |

| DN40X20 | 50.45 | 62 | 31.5 | 20.3 | 31.9 | 19 | 66 |

| DN40X25 | 50.45 | 60.25 | 31.5 | 40.4 | 49.8 | 26.5 | 67 |

| DN40X30 | 50.45 | 75 | 38 | 40.4 | 49.8 | 26.5 | 65.1 |

| DN40X32 | 63.5 | 75.9 | 38 | 25.3 | 31.9 | 19 | 79 |

| DN40X25 | 63.5 | 75.9 | 38 | 32.35 | 39.95 | 22.5 | 80 |

| DN40X32 | 63.5 | 75.9 | 38 | 40.4 | 49.8 | 26.5 | 80 |

| DN40X40 | 63.5 | 75.9 | 38 | 50.45 | 60.25 | 31.5 | 77.7 |

| DN40X25 | 75.5 | 88.91 | 44 | 32.35 | 39.95 | 22.5 | 93.5 |

| DN40X20 | 75.5 | 88.91 | 44 | 25.3 | 31.9 | 19 | 92.5 |

| DN40X30 | 75.5 | 88.91 | 44 | 50.45 | 60.25 | 31.5 | 93.5 |

| DN40X32 | 75.5 | 88.91 | 44 | 43.5 | 51.9 | 38 | 125.5 |

| DN40X25 | 90.55 | 105.15 | 51.5 | 32.35 | 39.95 | 22.5 | 108 |

| DN40X50 | 90.55 | 105.15 | 51.5 | 63.5 | 75.9 | 38 | 108 |

| DN40X65 | 90.55 | 105.15 | 51.5 | 75.5 | 88.91 | 44 | 107.3 |

| DN100X50 | 110.6 | 127.39 | 61.5 | 63.5 | 75.9 | 38 | 128 |

| DN100X65 | 110.6 | 127.39 | 61.5 | 75.5 | 88.91 | 44 | 128.6 |

| DN100X80 | 110.6 | 127.39 | 61.5 | 90.55 | 105.15 | 51.5 | 127.4 |

| DN125X50 | 140.6 | 161.4 | 76 | 90.55 | 105.15 | 61.5 | 138.3 |

| DN125X80 | 140.6 | 161.4 | 76 | 110.6 | 127.39 | 61.5 | 137.7 |

| DN150X100 | 160.7 | 184.5 | 86.5 | 110.6 | 127.39 | 61.5 | 180.2 |

| DN150X125 | 160.7 | 184.5 | 86.5 | 140.6 | 161.4 | 76 | 177.3 |

| DN200X115 | 200 | 228.1 | 106.2 | 110 | 127.5 | 61.5 | 217 |

| DN200X160 | 200 | 228.1 | 106.2 | 160 | 184.9 | 86.5 | 217 |

| DN200X100 | 226.2 | 253.8 | 118.5 | 110.6 | 127.39 | 61.5 | 244.5 |

| DN200X150 | 226.2 | 253.8 | 118.5 | 160.7 | 184.5 | 86.5 | 242.5 |

| DN200X200 | 226.2 | 283.8 | 131.5 | 160 | 184.9 | 86.5 | 270 |

| DN200X225 | 200 | 263.4 | 131.5 | 226 | 253.8 | 118.5 | 270 |

| DN200X225 | 281.5 | 315.5 | 149 | 226.2 | 253.8 | 118 | 304 |

| DN280X160 | 281.5 | 315.5 | 149 | 160.8 | 185 | 85 | 304 |

| DN315X225 | 316.7 | 355 | 166 | 226.2 | 253.8 | 118 | 355 |

| DN315X160 | 316.7 | 355 | 166 | 160.8 | 185 | 85 | 355 |

| DN355X135 | 356.8 | 395 | 186 | 316.7 | 355 | 162 | 385 |

| DN355X225 | 356.8 | 395 | 186 | 226.2 | 253.8 | 118 | 385 |

| DN400X135 | 400 | 442 | 208 | 316.7 | 355 | 162 | 440 |

| DN400X160 | 402 | 442 | 205 | 356.8 | 395 | 162 | 440 |