Overview of Positive Tee Pipe

Key Features of Positive Tee Pipe

1. Superior Flow Distribution

2. Robust Composite Construction

3. Electrofusion Compatibility

4. Chemical and UV Resistance

5. Versatile Sizing and Configuration

Typical Applications of Positive Tee Pipe

Water Distribution Systems

Industrial Chemical Processing

Agricultural Irrigation Systems

Mining and Dewatering Operations

Gas Distribution Networks

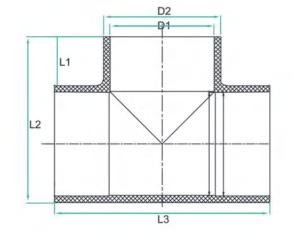

Technical Specifications

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SIZE | NO. | D1 | D2 | L1 | L2 | L3 |

| DN15 | ST15 | 20.3 | 26.3 | 16.5 | 41.12 | 56 |

| DN20 | ST20 | 25.3 | 31.9 | 19 | 48.93 | 66 |

| DN25 | ST25 | 32.35 | 39.95 | 22.5 | 59.96 | 80 |

| DN32 | ST32 | 40.4 | 49.8 | 26.5 | 72.73 | 96 |

| DN40 | ST40 | 50.45 | 60.25 | 31.5 | 88.27 | 116 |

| DN50 | ST50 | 63.5 | 75.9 | 38 | 109.09 | 142 |

| DN65 | ST65 | 75.5 | 88.91 | 44 | 127.47 | 166 |

| DN80 | ST80 | 90.55 | 105.15 | 51.5 | 150.12 | 196 |

| DN100 | ST100 | 110.6 | 127.39 | 61.5 | 181.92 | 236 |

| DN125 | ST125 | 140.6 | 161.4 | 76 | 228.82 | 295.5 |

| DN150 | ST150 | 160.7 | 184.5 | 86.5 | 260.8 | 335 |

| DN200 | ST200 | 200 | 228.1 | 106.2 | 322.05 | 416 |

| DN250 | ST250 | 226.2 | 253.8 | 118.5 | 361 | 466.5 |

| DN250 | ST250 | 250 | 283.4 | 131.5 | 400.2 | 517 |

| DN250 | ST250 | 281.5 | 315.5 | 147 | 446 | 580 |

| DN300 | ST300 | 316.7 | 355 | 165 | 504 | 654 |

| DN350 | ST350 | 356.8 | 395 | 185 | 566 | 738 |

| DN400 | ST400 | 402 | 442 | 208 | 634 | 828 |

| DN250(PN10) | ST250 | 280.6 | 306 | 147 | 448 | 552 |

| DN300(PN10) | ST300 | 315.7 | 344 | 165 | 502 | 453 |

| DN350(PN10) | ST350 | 355.8 | 385 | 183.5 | 564 | 736.5 |

| DN400(PN10) | ST400 | 401 | 432 | 208 | 634 | 826 |