Product Overview

Features of UPVC Direct Coupling

-

Exceptional Corrosion Resistance: Highly resistant to acids, alkalis, and chemical corrosion, making it ideal for industrial effluents, agricultural chemicals, and saline water environments without degradation. -

Leak-Free Solvent Cement Joints: Designed for simple socket-end connections using UPVC-specific cement, ensuring robust, permanent bonds that withstand pressures of PN10-PN16 (1.0–1.6 MPa). -

Smooth Interior Surface: The precision-molded inner wall minimizes friction loss, prevents clogging from sediment or scale, and maintains optimal flow efficiency in water or chemical transport. -

Lightweight and Easy Installation: Up to 50% lighter than metal equivalents, reducing handling effort and labor costs. Installation involves basic steps: apply cement, insert pipes, and allow setting. -

Long Service Life: Rated for temperatures from 0°C to 60°C (SCH80 variants handle up to 75°C) and pressures up to PN16, ensuring over 50 years of reliable service with minimal maintenance. -

Eco-Friendly and Potable Water Safe: Complies with drinking water standards (e.g., ISO 4422), featuring non-toxic, odorless material suitable for freshwater systems.

Typical Uses of UPVC Direct Coupling

-

Potable Water Distribution: Connects straight pipeline sections in municipal or residential water networks. Its non-corrosive nature ensures no taste, color, or odor contamination, unlike metal pipes. -

Industrial Chemical Lines: Ideal for plants transporting corrosive fluids, acids, or alkalis, where chemical resistance prevents leaks and extends system lifespan. -

Agricultural Irrigation: Joins main and branch lines in sprinkler or drip systems, resisting fertilizers and pesticides while enduring UV exposure in outdoor settings. -

Mining and Drainage: Used in dewatering or ventilating mines to connect pipes carrying abrasive or acidic liquids, thanks to durability and easy installation in confined spaces. -

Electrical Conduit Systems: Provides straight runs for cable protection, acting as an insulating sleeve that safeguards against moisture and physical damage.

Range of Production

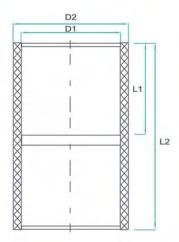

| SIZE | Number | D1 | D2 | L1 | L2 |

| DN15 | ZJ15 | 20.3 | 26.3 | 16.5 | 34.4 |

| DN20 | ZJ20 | 25.3 | 31.9 | 19 | 39 |

| DN25 | ZJ25 | 32.35 | 39.95 | 22.5 | 46.27 |

| DN32 | ZJ32 | 40.4 | 49.8 | 26.5 | 54.38 |

| DN40 | ZJ40 | 50.45 | 60.25 | 31.5 | 64.39 |

| DN50 | ZJ50 | 63.5 | 75.9 | 38 | 85.11 |

| DN65 | ZJ65 | 75.5 | 88.91 | 44 | 90.16 |

| DN80 | ZJ80 | 90.55 | 105.15 | 51.5 | 106.32 |

| DN100 | ZJ100 | 110.6 | 127.39 | 61.5 | 138.49 |

| DN125 | ZJ125 | 140.6 | 161.4 | 76 | 159.61 |

| DN150 | ZJ150 | 160.7 | 184.5 | 86.5 | 179.35 |

| dn200 | ZJ200 | 200 | 228.1 | 106.2 | 218 |

| DN200 | ZJ200 | 226.2 | 253.8 | 118.5 | 243.03 |

| dn250 | ZJ250 | 250 | 281.89 | 131.5 | 268 |

| DN250 | ZJ250 | 281.5 | 315.5 | 147 | 299 |

| DN300 | ZJ300 | 316.7 | 355 | 165 | 343 |

| DN350 | ZJ350 | 356.8 | 395 | 185 | 376 |

| DN400 | ZJ400 | 402 | 442 | 208 | 424 |

| DN250 (PN10) | ZJ250 | 280.6 | 306 | 147 | 299 |

| DN300 (PN10) | ZJ300 | 315.7 | 344 | 166 | 343 |

| DN350 (PN10) | ZJ350 | 355.8 | 385 | 183.5 | 373 |

| DN400 (PN10) | ZJ400 | 401 | 432 | 208 | 423 |