Introduction of UPVC 90° Elbow

Sikerui UPVC 90° Elbow is a precision-engineered pipe fitting manufactured from unplasticized polyvinyl chloride (UPVC), designed to provide reliable 90-degree directional changes in piping systems. This fitting excels in demanding applications where corrosion resistance, durability, and efficient flow characteristics are essential. With its robust construction and smooth interior surface, the UPVC 90° Elbow ensures minimal pressure loss while maintaining optimal flow efficiency in various industrial, commercial, and residential piping systems.

Engineered to meet rigorous international standards, this elbow fitting offers exceptional resistance to chemical corrosion, UV radiation, and environmental stressors, making it suitable for diverse applications from water supply to chemical transportation. The product’s lightweight nature simplifies installation while maintaining structural integrity under pressure, providing a cost-effective alternative to traditional metal fittings.

Features of UPVC 90° Elbow

-

Superior Corrosion Resistance: Manufactured from high-quality UPVC material, the 90° elbow demonstrates excellent resistance to acids, alkalis, and various chemical corrosions, making it ideal for industrial applications and harsh environments. -

Optimized Flow Design: The smooth interior surface minimizes fluid friction resistance, reduces pressure loss, and prevents clogging accumulation, maintaining high flow efficiency throughout the system’s lifespan. -

Robust Construction: Available in Schedule 80 (SCH-80) thickness for higher pressure applications, these elbows feature enhanced durability and pressure tolerance compared to standard fittings, with a maximum working temperature of 140°F (60°C) . -

Lightweight and Easy Installation: The lightweight design simplifies handling and reduces installation time and costs. Connections can be efficiently made through solvent cement bonding or threading, ensuring secure, leak-proof joints. -

Chemical and UV Resistance: Resistant to most chemicals and ultraviolet rays, making it suitable for both indoor and outdoor applications without concerns about degradation or weakening over time. -

Long Service Life: With a service life exceeding 50 years, UPVC 90° elbows maintain their integrity under various operating conditions, offering reliable performance in diverse temperature and pressure environments.

Typical Uses of UPVC 90° Elbow

-

Water Supply and Drainage Systems: Widely used in building water supply and drainage pipelines to create efficient directional changes while ensuring unobstructed water flow. The corrosion resistance of UPVC material makes it ideal for municipal water systems. -

Chemical Transportation: In industrial settings, these elbows are employed to transport various chemical liquids, acid-base solutions, and other corrosive substances, providing long-term stability in aggressive chemical environments. -

Ventilation Systems: Effectively used in ventilation systems to change airflow direction by 90 degrees, ensuring optimal system performance and efficient air distribution. -

Electrical Conduit Systems: The non-conductive properties of UPVC make these elbows ideal for electrical conduit applications, providing cable protection and directional changes while enhancing safety in electrical installations. -

Agricultural Irrigation: Used in agricultural irrigation systems to facilitate pipeline direction changes in fields, offering excellent UV resistance and durability in outdoor environments. -

Mining and Industrial Applications: Suitable for draining corrosive liquids in mining operations and industrial plants, where their corrosion resistance and easy installation provide significant advantages over traditional materials.

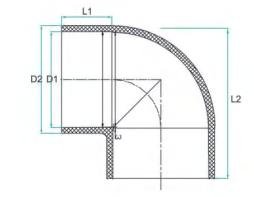

Product Range and Specifications of ELBOW 90°

|

规格(SIZE) |

NO. | D1 | D2 | L1 | L2 |

|

DN15 |

WT15 | 20.3 | 26.3 | 16.5 | 41.25 |

|

DN20 |

WT20 | 25.3 | 31.9 | 19 | 49.1 |

| DN25 | WT25 | 32.35 | 39.95 | 22.5 |

60.7 |

|

DN32 |

WT32 | 40.4 | 49.8 | 26.5 | 72.87 |

|

DN40 |

WT40 | 50.45 | 60.25 | 31.5 |

88 |

| DN50 | WT50 | 63.5 | 75.9 | 38 |

108.82 |

|

DN65 |

WT65 | 75.5 | 88.91 | 44 | 127.47 |

| DN80 | WT80 | 90.55 | 105.15 | 51.5 |

150.65 |

|

DN100 |

WT100 | 110.6 | 127.39 | 61.5 | 181.66 |

| DN125 | WT125 | 140.6 | 161.4 | 76 |

228.09 |

|

DN150 |

WT150 | 160.7 | 184.5 | 86.5 | 260.52 |

| dn200 | wt200 | 200 | 228.1 | 106.2 |

324 |

|

DN200 |

WT200 | 226.2 | 253.8 | 118.5 | 360.29 |

| dn250 | wt250 | 250 | 283.4 | 131.5 |

402.5 |

|

DN250 |

WT250 | 281.5 | 315.5 | 147 | 446 |

| DN300 | WT300 | 316.7 | 355 | 165 |

504 |

|

DN350 |

WT350 | 356.8 | 395 | 185 | 566 |

| DN400 | WT400 | 402 | 442 | 208 |

634 |

|

DN250 (PN10) |

WT250 | 280.6 | 306 | 147 | 440 |

| DN300 (PN10) | WT300 | 315.7 | 344 | 165 |

495 |

| DN350 (PN10) |

WT350 |

355.8 | 385 | 183.5 |

558 |

| DN400 (PN10) | WT400 | 401 | 432 | 208 |

620 |

FAQs of Sikerui UPVC 90° Elbow

Q1: Can your company customize UPVC 90° elbows for specific project requirements?

Yes, we offer comprehensive customization options for UPVC 90° elbows, including specific dimensions, pressure ratings (SCH-40, SCH-80), connection types (socket, threaded), and special material formulations to meet unique application needs.

Q2: What quality certifications do your UPVC 90° elbows hold?

Our products adhere to international standards including DIN, ASTM, ISO, and BS, with certifications such as ISO9001 for quality management systems. Specific products may also carry KITEMARK, NSF, or other regional certifications upon request.

Q3: What is the maximum temperature and pressure rating for these elbows?

The standard UPVC 90° elbows can withstand temperatures up to 140°F (60°C) with pressure ratings varying by schedule class. SCH-80 elbows provide higher pressure tolerance for demanding applications.

Q4: How does the installation of UPVC 90° elbows compare to metal alternatives?

UPVC elbows are significantly lighter than metal equivalents, making them easier to handle and install. They can be quickly connected using solvent cement or threading, reducing labor time and costs without specialized equipment.

Q5: What is the lead time for samples and bulk orders?

Sample elbows are typically available within one week after specification confirmation. Bulk order delivery generally takes 2-3 weeks after order confirmation, with variations based on order quantity and customization requirements.