Product Introduction

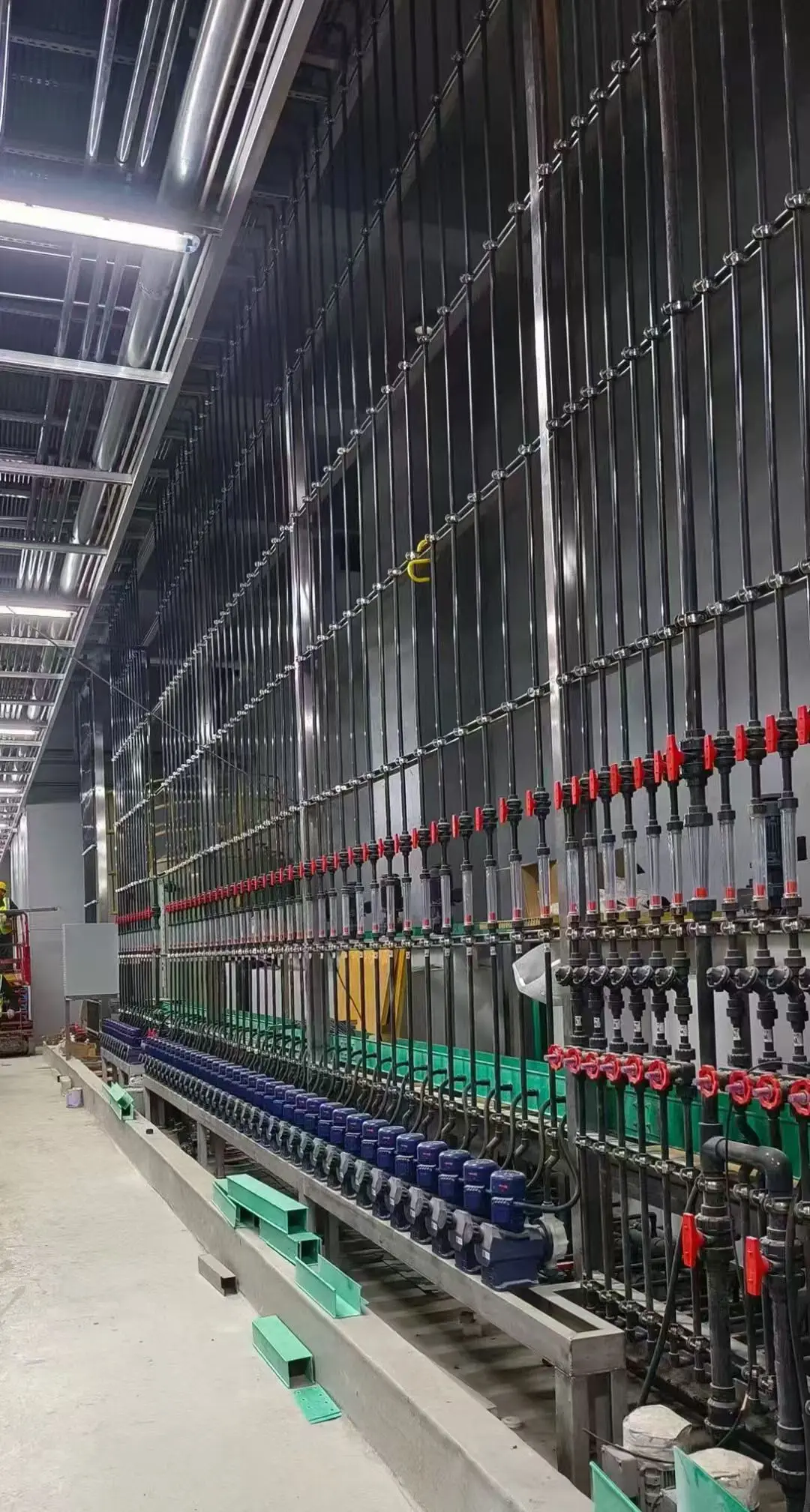

Sikerui UPVC Pipeline is a high-performance plumbing and industrial solution engineered from Unplasticized Polyvinyl Chloride (UPVC), renowned for its exceptional durability, corrosion resistance, and cost-effectiveness. Designed to meet rigorous international standards, these pipes excel in demanding environments, including water supply, chemical transportation, drainage systems, and agricultural irrigation. With a service life exceeding 50 years, UPVC pipelines combine lightweight simplicity with robust performance, making them a sustainable alternative to traditional metal pipes. Their smooth interior surface ensures optimal flow efficiency, while resistance to chemicals, UV radiation, and abrasion guarantees long-term reliability in diverse applications.

Key Features of UPVC Pipeline

-

Superior Corrosion Resistance – Highly resistant to acids, alkalis, and chemical corrosion, ideal for industrial and agricultural use. -

Lightweight and Easy Installation – Up to 50% lighter than metal pipes, reducing transport and labor costs while simplifying handling. -

Smooth Interior Surface – Minimizes friction loss, prevents clogging, and maintains high flow efficiency (hydraulic efficiency 30% higher than cast iron pipes). -

Long Service Life – Designed to withstand extreme temperatures (0°C–60°C) and pressure ratings of 1.0–1.6 MPa for over 50 years. -

Eco-Friendly and Non-Toxic – Complies with drinking water safety standards (e.g., ISO 4422, GB/T 10002.1), ensuring safe potable water transport. -

Versatile Applications – Suitable for potable water systems, sewage drainage, chemical processing, electrical conduits, and irrigation projects.

Typical Applications of UPVC Pipeline

Water Supply

Irrigation Systems

Industrial Applications

Soil, Waste, and Drainage Systems

Mining

Electrical & Telecommunications Cables:

Since S&M UPVC pipes are themselves form an integral insulator, there is an ever-increasing demand for them as electrical conduit. To facilitate work, a full line of fittings is available and fabricated from the same material as the pipes.

Range of production:

Pipes from S&M are manufactured according to Jordanian, DIN Standards from 16mm up to 630mm outside diameter in various pressure classes, details of which are shown later in our catalog.

Pipe(DIN)(GB/T4219.1-2008)

| Nominal Size | Socket Type | |||||

| D (mm) | Tolerance | S6.3 | S10 | |||

| T (min/mm) | Tolerance | T (min/mm) | Tolerance | |||

| DN15 | 20 | +0.20 | 2.3 | +0.40 | 2.0 | +0.40 |

| DN20 | 25 | +0.20 | 2.8 | +0.50 | 2.0 | +0.40 |

| DN25 | 32 | +0.20 | 3.6 | +0.50 | 2.4 | +0.50 |

| DN32 | 40 | +0.20 | 3 | +0.50 | 2.0 | +0.50 |

| DN40 | 50 | +0.20 | 3.7 | +0.60 | 2.4 | +0.50 |

| DN50 | 63 | +0.30 | 4.7 | +0.70 | 3.0 | +0.50 |

| DN65 | 75 | +0.30 | 5.6 | +0.80 | 3.6 | +0.60 |

| DN80 | 90 | +0.30 | 6.7 | +0.90 | 4.3 | +0.70 |

| DN100 | 110 | +0.40 | 8.1 | +1.10 | 5.3 | +0.80 |

| DN125 | 140 | +0.50 | 10.3 | +1.30 | 6.7 | +0.90 |

| DN150 | 160 | +0.50 | 11.8 | +1.40 | 7.7 | +1.00 |

| DN180 | 200 | +0.60 | 14.7 | +1.70 | 9.6 | +1.20 |

| DN200 | 225 | +0.70 | 16.6 | +1.90 | 10.8 | +1.30 |

| DN250 | 250 | +0.80 | 18.4 | +2.10 | 11.9 | +1.40 |

| DN250 | 280 | +0.90 | 20.6 | +2.30 | 13.4 | +1.60 |

| DN300 | 315 | +1.00 | 23.2 | +2.60 | 15.0 | +1.70 |

| DN350 | 355 | +1.10 | 26.1 | +2.90 | 16.9 | +1.90 |

| DN400 | 400 | +1.20 | 29.4 | +3.20 | 19.1 | +2.20 |

Pipe(Schedule80)(Schedule40)(F441-99)

| Nominal Size | Socket Type | |||||

| D (MM) | Tolerance | SCH80 | SCH40 | |||

| T (min/mm) | Tolerance | T (min/mm) | Tolerance | |||

| 1/2″ | 21.34 | ±0.10 | 3.73 | +0.51 | 2.77 | +0.51 |

| 3/4″ | 26.67 | ±0.10 | 3.91 | +0.51 | 2.87 | +0.51 |

| 1″ | 33.40 | ±0.13 | 4.55 | +0.53 | 3.38 | +0.51 |

| 1–1/4″ | 42.16 | ±0.13 | 4.85 | +0.58 | 3.56 | +0.51 |

| 1–1/2″ | 48.26 | ±0.15 | 5.08 | +0.61 | 3.68 | +0.51 |

| 2″ | 60.32 | ±0.15 | 5.54 | +0.66 | 3.91 | +0.51 |

| 2–1/2″ | 73.02 | ±0.18 | 7.01 | +0.84 | 5.16 | +0.61 |

| 3″ | 88.90 | ±0.20 | 7.62 | +0.91 | 5.49 | +0.66 |

| 4″ | 114.30 | ±0.23 | 8.56 | +1.02 | 6.02 | +0.71 |

| 5″ | 141.30 | ±0.25 | 9.52 | +1.14 | 6.55 | +0.79 |

| 6″ | 168.28 | ±0.28 | 10.97 | +1.32 | 7.11 | +0.86 |

| 8″ | 219.08 | ±0.38 | 12.70 | +1.52 | 8.18 | +0.99 |

| 10″ | 273.50 | ±0.38 | 15.06 | +1.80 | 9.27 | +1.12 |

| 12″ | 323.85 | ±0.38 | 17.45 | +2.08 | 10.31 | +1.24 |

| 14″ | 355.60 | ±0.38 | 19.05 | +2.28 | 11.10 | +1.35 |

Customization and Compliance

Sikerui offers customizable UPVC pipelines in sizes from DN20 to DN800, with options for pressure ratings, thickness, and connection methods (e.g., solvent cement joints). All products adhere to GB/T 4219.1-2008 and ISO standards, backed by SGS/CE certifications for global export.

FAQs of Sikerui UPVC Pipeline

Q1: Can your company customize products?

A: Yes, Sikerui Pipe is a leading supplier of UPVC piping systems. We work closely with clients to provide tailored solutions, offering customization in dimensions (from DN15 to DN600), pressure ratings, and specific application requirements for various industrial and construction needs.

Q2: How can I get a sample to check quality?

A: We can provide sample sections of our UPVC pipes for quality evaluation. Samples are typically prepared within one week after specifications are agreed upon, allowing you to verify material quality and performance characteristics .

Q3: What about your delivery time? Can we receive our goods on time?

A: Our standard delivery time is approximately 2-3 weeks after order confirmation. The exact timeline depends on the order quantity and product specifications. Common standard sizes are often available for quicker dispatch.

Q4: What quality assurance measures govern your manufacturing process?

Our production follows rigorous quality control protocols in accordance with international standards for UPVC fittings. Each Positive Cross Tube undergoes dimensional verification, pressure testing, and visual inspection to ensure consistent performance.

Q5: How does your delivery system handle large-volume industrial projects?

For substantial orders, we implement project-specific logistics planning with standard delivery timelines of 3-4 weeks after order confirmation. Our global shipping capabilities ensure reliable delivery even for time-sensitive industrial projects.