Overview of Internal Thread Bushing

Key Features of Internal Thread Bushing

Exceptional Durability and Thread Protection

Vibration Resistance and Secure Fastening

Material Versatility and Compatibility

Repair and Restoration Capability

Corrosion and Chemical Resistance

Typical Applications of Internal Thread Bushing

Aerospace and Defense Systems

Automotive and Transportation

Industrial Machinery and Equipment

Electronics and Telecommunications

Pipe Systems and Fluid Handling

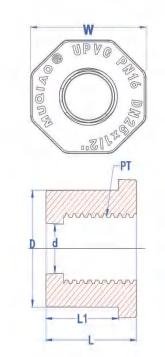

Technical Specifications

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SIZE | D | d | L1 | L | W | PT |

| DN15*1/4″ | 20 | 7 | 17 | 22.5 | 24.5 | 19 |

| DN15*3/8″ | 20 | 11 | 17 | 22.5 | 25 | 19 |

| DN20*1/2″ | 25 | 16 | 20 | 26.5 | 30 | 14 |

| DN25*1/2″ | 32 | 16 | 23.5 | 29.5 | 38 | 14 |

| DN25*3/4″ | 32 | 21 | 23.5 | 29.5 | 38 | 14 |

| DN32*1″ | 40 | 29 | 25.5 | 31.5 | 45 | 11 |

| DN40*1–1/4″ | 50 | 38 | 26.5 | 30 | 11 | |

| DN50*1–1/2″ | 63 | 50 | 31.5 | 35 | 11 |