Product Overview

Features of UPVC Reducing Cross

-

Multi-Directional Flow Optimization – Engineered with four outlets of varying diameters to enable seamless flow splitting or combining, reducing turbulence and maintaining pressure efficiency in complex pipeline networks . -

Superior Chemical Resistance – Highly resistant to acids, alkalis, and corrosive fluids, ensuring safe transport of aggressive chemicals in industrial and mining applications . -

Lightweight and Easy Installation – Up to 50% lighter than metal crosses, simplifying handling and reducing labor costs. Compatible with solvent cement, threaded, or rubber gasket connections for quick assembly . -

Smooth Interior Surface – Precision-molded to minimize friction loss, prevent clogging, and maintain optimal flow rates in water, sewage, or chemical transport systems . -

Durable Under Pressure – Rated for pressures up to PN16 (1.6 MPa) and temperatures from 0°C to 60°C, with robust SCH80 options for high-stress environments . -

Eco-Friendly and Safe – Complies with drinking water standards (e.g., NSF/ANSI, ISO 4422), ensuring non-toxic operation for potable water systems .

Typical Uses of UPVC Reducing Cross

-

Water Distribution Networks: Used in municipal water supply systems to branch into smaller lines for residential or commercial buildings, ensuring efficient flow division without corrosion or contamination risks . -

Industrial Chemical Processing: Ideal for plants handling acids, alkalis, or abrasive fluids, where its chemical resistance enables safe diversion of streams to equipment with varying inlet sizes . -

Mine Drainage Systems: Effectively manages corrosive liquid removal in mining operations, withstanding acidic water and abrasive particles while ensuring long-term reliability in underground environments . -

Agricultural Irrigation: Facilitates precise water distribution from main lines to smaller sub-lines in large-scale farms, resisting fertilizers and pesticides without degradation . -

Sewage and Ventilation Systems: Employed in drainage networks to combine or split waste flows, with smooth walls preventing blockages. Also used for venting corrosive gases in industrial facilities .

Range of Production

|

SIZE |

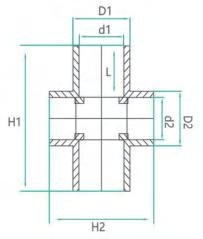

Number | D1 | d1 | D2 | d2 | L | I | H1 | H2 |

|

DN80x40 |

YS80x40 | 105.15 | 90.55 | 60.25 | 50.45 | 51.5 | 31.5 | 154.6 | 154.5 |

|

DN80x50 |

YS80x50 | 105.15 | 90.55 | 75.9 | 43.5 | 51.5 | 38 | 166.8 | 167 |

|

DN100x40 |

YS100x40 | 127.39 | 110.6 | 60.25 | 50.45 | 61.5 | 31.5 | 174 |

174 |

| DN100x50 | YS100x50 | 127.39 | 110.6 | 75.9 | 63.5 | 61.5 | 38 | 186.8 |

187 |

|

DN125x40 |

YS125x40 | 161.4 | 140.6 | 60.25 | 50.45 | 76 | 31.5 | 205 | 204.9 |

| DN125x50 | YS125x50 | 161.4 | 140.6 | 75.9 | 63.5 | 76 | 38 | 218 |

218 |

|

DN125x65 |

YS125x65 | 161.4 | 140.6 | 88.91 | 75.5 | 76 | 44 | 230 |

230 |

| DN150x50 | YS150x50 | 184.5 | 160.7 | 75.9 | 63.5 | 86.5 | 38 | 238.6 |

238.8 |

| DN150x100 | YS150x100 | 184.5 | 160.7 | 127.39 | 110.6 | 86.5 | 61.5 | 285.8 |

286 |