Overview of Pipe Union

Key Features of Pipe Union

-

Detachable Design for Maintenance Efficiency Unions feature a nut-based locking mechanism that allows repeated assembly and disassembly without damaging pipes or seals . This eliminates the need for welding or threading during repairs, reducing downtime in industrial systems . Example: A loose nut can be tightened or loosened with standard tools, enabling swift component replacement . -

Leak-Proof Sealing Under Pressure Precision-machined seating surfaces (e.g., conical, flat-faced) with gaskets or metal-to-metal contact ensure bubble-tight seals up to 3000 PSI . Materials like EPDM or PTFE gaskets add chemical resistance for aggressive media . Application: Hydraulic systems use unions with O-rings to prevent fluid leakage under dynamic pressure . -

Material Versatility for Diverse Environments Available in stainless steel (304/316) for corrosion resistance, brass for water applications, and PVC for chemical compatibility, unions adapt to various media including steam, oils, and acids . Special coatings (e.g., zinc plating) enhance durability in outdoor or marine settings . -

Pressure and Temperature Resilience Unions maintain integrity across extreme conditions: -

Temperature Range: -20°C to 150°C (standard); up to 300°C for high-temperature alloys . -

Pressure Ratings: 150 PSI to 3000 PSI, depending on size and material . Standard Compliance: ASME B16.39, ISO 4144, and DIN standards ensure safety .

-

-

Easy Installation with Standard Tools Lightweight and compact, unions require only wrenches for assembly, avoiding specialized equipment . Their uniform thread patterns (NPT, BSP) prevent cross-threading errors . Benefit: Reduces installation time by up to 50% compared to welded joints . -

Alignment Tolerance for Misalignment Compensation Flexible designs (e.g., swing unions) accommodate angular deviation or vibration, preventing stress accumulation in pipelines . Ideal for pumps, compressors, and rotating equipment .

Typical Applications of Pipe Union

-

Industrial Maintenance: Enable quick disassembly for pump, valve, or instrument servicing in chemical plants . -

Hydraulic Systems: Provide leak-free connections in high-pressure fluid power applications . -

Water Treatment: Facilitate filter or pump replacement in municipal water plants with brass or stainless unions . -

HVAC and Refrigeration: Copper unions allow easy compressor or coil maintenance without brazing . -

Oil and Gas Pipelines: Flanged unions withstand high pressure in upstream and midstream operations .

Technical Specifications

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

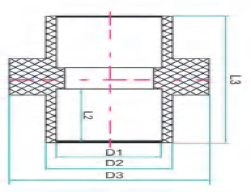

| SIZE | Number | D1 | D2 | D3 | L1 | L2 |

| DN15 | YL15 | 20.3 | 26.3 | 54 | 47 | 16.5 |

| DN20 | YL20 | 25.3 | 31.9 | 63 | 59 | 19 |

| DN25 | YL25 | 32.35 | 39.95 | 73.5 | 67 | 22.5 |

| DN32 | YL32 | 40.4 | 49.8 | 84.5 | 76 | 26.5 |

| DN40 | YL40 | 50.45 | 60.25 | 98 | 80 | 31.5 |

| DN50 | YL50 | 63.5 | 75.9 | 119 | 94 | 38 |

| DN65 | YL65 | 75.5 | 88.91 | 150 | 120 | 44 |

| DN80 | YL80 | 90.55 | 105.15 | 169 | 152 | 51.5 |

| DN100 | YL100 | 110.6 | 127.39 | 190 | 175 | 61.5 |