Overview of Ball Bottom Valve

Key Features of Ball Bottom Valve

Zero-Residue Design

Hygienic and Sanitary Construction

High-Performance Sealing System

Versatile Actuation Options

Robust Construction Materials

Typical Applications of Ball Bottom Valve

Pharmaceutical and Bioprocessing

Food and Beverage Industry

Chemical and Petrochemical Plants

Mining and Mineral Processing

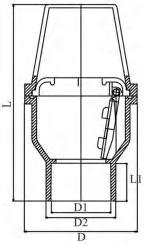

Technical Specifications

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SIZE | Number | D | D1 | D2 | L | L1 |

| 1-1/2″(DN40) | FD40 | 105.00 | 50.45 | 60.50 | 200.00 | 37.70 |

| 2″(DN50) | FD50 | 124.20 | 63.50 | 75.90 | 220.00 | 38.30 |

| 2-1/2(DN65) | FD65 | 145.00 | 75.50 | 88.91 | 260.00 | 44.80 |

| 3″(DN80) | FD80 | 163.00 | 90.55 | 105.15 | 300.00 | 56.70 |

| 4″(DN100) | FD100 | 190.00 | 110.60 | 127.39 | 370.00 | 75.10 |

| 5″(DN125) | FD125 | 247.00 | 140.60 | 164.40 | 400.00 | 95.00 |

| 6″(DN150) | FD150 | 270.00 | 160.70 | 184.50 | 485.00 | 99.90 |

| 8″(φ200) | FD200 | 344.60 | 200.90 | 225.00 | 510.00 | 124.80 |