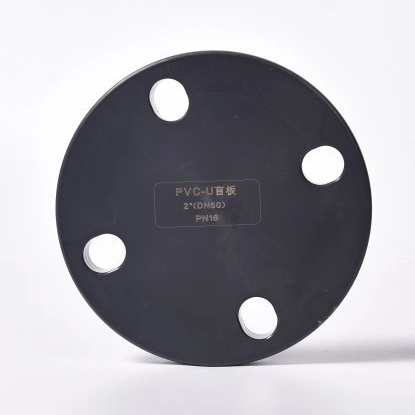

Product Overview of UPVC Blind Flange

Key Features of UPVC Blind Flange

Exceptional Corrosion Resistance

Lightweight Construction with Robust Mechanical Strength

Reliable Sealing Performance

Thermal and Electrical Properties

Smooth Surface and Hygienic Properties

Applications of UPVC Blind Flange

Isolation for Maintenance and Safety

Chemical and Industrial Processing

Water and Wastewater Treatment

Multi-System Pipeline Configurations

Specialized Configurations: Figure-8 Blind Flanges

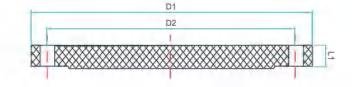

Technical Specifications

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SIZE | Number | D1 | D2 | L1 | r-φe |

| DN15 | MBL15 | 95 | 65 | 12 | 4-φ18 |

| DN20 | MBL20 | 105 | 75 | 13.4 | 4-φ18 |

| DN25 | MBL25 | 115 | 85 | 15 | 4-φ18 |

| DN32 | MBL32 | 140 | 100 | 16 | 4-φ18 |

| DN40 | MBL40 | 150 | 110 | 17.5 | 4-φ18 |

| DN50 | MBL50 | 165 | 125 | 19 | 4-φ18 |

| DN65 | MBL65 | 185 | 145 | 22.3 | 4-φ18 |

| DN80 | MBL80 | 200 | 160 | 22.8 | 8-φ18 |

| DN100 | MBL100 | 220 | 180 | 25 | 8-φ18 |

| DN125 | MBL125 | 250 | 210 | 32 | 8-φ18 |

| DN150 | MBL150 | 285 | 240 | 33 | 8-φ22 |

| DN200 | MBL200 | 340 | 295 | 34 | 8-φ22 |