Overview of Reducing Bush

Sikerui Reducing Bush (also known as a reducer bushing) is a precision-engineered pipe fitting designed to create a secure transition between pipes of different diameters in plumbing, industrial, and mechanical systems . This concentric or eccentric sleeve-shaped component enables efficient size reduction within piping networks, ensuring smooth flow transition while maintaining structural integrity and pressure rating . Manufactured from materials including carbon steel, stainless steel, PVC, brass, and malleable iron, reducing bushes accommodate diameter reductions typically ranging from 1/8 inch to 4 inches (DN6 to DN100) while withstanding temperatures from -20°C to 400°C and pressures up to 3000 PSI depending on material specifications .

Reducing bushes feature a threaded (NPT, BSP) or socket-weld design that facilitates easy installation without requiring special tools, making them ideal for space-constrained applications where conventional reducers would be impractical . Engineered to meet international standards including ASME B16.9, ISO 4144, and DIN 2605, these components provide reliable performance in chemical processing, water supply, oil and gas, and industrial piping systems . Their compact design minimizes turbulence and pressure drop while offering a cost-effective solution for system modifications and adaptations, with a service life exceeding 20 years in standard operating conditions . The reducing bush’s versatility and installation efficiency make it indispensable for maintenance, repairs, and new installations across multiple industries .

Key Features of Reducing Bush

Space-Saving Design

Reducing bushes provide a compact alternative to conventional reducers, requiring significantly less installation space while maintaining full pressure containment capabilities . Their sleeve-shaped design allows direct connection between dissimilar pipe sizes without additional fittings, simplifying system layout and reducing potential leak points in confined spaces . This characteristic is particularly valuable in equipment skids, instrumentation lines, and retrofit applications where space optimization is critical .

Material Versatility and Compatibility

Available in diverse materials including carbon steel (ASTM A234), stainless steel (304/316L), brass, PVC, and specialty alloys, reducing bushes can be selected to match specific application requirements regarding corrosion resistance, temperature tolerance, and pressure capacity . This material adaptability ensures compatibility with various media including water, chemicals, hydrocarbons, and steam, while maintaining performance under demanding operating conditions . Selective applications may require specific materials to avoid soil toxicity or chemical interactions .

Pressure and Temperature Resilience

Reducing bushes maintain structural integrity under extreme conditions, with pressure ratings matching schedule 40 to 160 piping systems and temperature tolerance ranging from cryogenic -20°C to high-temperature 400°C applications . The uniform wall thickness and precision machining ensure even stress distribution, preventing failure points at critical transitions where pressure and temperature fluctuations occur . This reliability makes them suitable for demanding applications in power generation, process industries, and HVAC systems .

Installation Efficiency

The simple threaded or socket-weld design enables quick installation without specialized tools or extensive training, significantly reducing labor time compared to alternative reduction methods . Installation requires basic wrench tightening for threaded versions or standard welding procedures for socket-weld types, with no complex alignment or special preparation needed . This efficiency translates to substantial cost savings in maintenance and modification projects, particularly in time-sensitive industrial shutdowns .

Flow Optimization

Properly designed reducing bushes minimize turbulence and pressure drop at diameter transition points, maintaining system efficiency while accommodating necessary size changes . The concentric design (for aligned pipelines) or eccentric configuration (for horizontal pipes requiring air elimination) ensures optimal flow characteristics based on specific application requirements . This hydraulic efficiency contributes to reduced energy consumption and improved system performance in pumping and fluid transfer applications .

Typical Applications of Reducing Bush

Instrumentation and Control Systems

Reducing bushes provide precise connections between main process lines and instrument taps, enabling accurate pressure, temperature, and flow measurements without significant system modifications . Their compact design is ideal for crowded instrument panels and gauge installations where space is limited, while maintaining seal integrity under vibration and pressure cycling conditions typical in control systems .

Pump and Equipment Connections

In pump discharge and suction piping, reducing bushes facilitate efficient transitions between equipment nozzles and main piping, accommodating different size requirements while minimizing space requirements . The concentrated design handles vibration and thermal expansion better than multiple fitting arrangements, reducing stress on equipment connections and improving system reliability in critical applications .

Hydraulic and Pneumatic Systems

Reducing bushes ensure leak-free connections in high-pressure hydraulic and pneumatic systems where space constraints prohibit conventional reducers . Their robust construction withstands pressure surges and cyclic loading while maintaining seal integrity, making them ideal for mobile equipment, industrial machinery, and automation systems requiring reliable performance in confined spaces .

Chemical Processing Plants

The corrosion-resistant materials available for reducing bushes make them suitable for aggressive chemical applications, providing reliable service in acid, alkali, and solvent handling systems where conventional materials would fail . The seamless transition minimizes areas for sediment accumulation or corrosion initiation, enhancing system longevity and maintenance intervals in demanding process environments .

Water Treatment and Irrigation Systems

In water distribution, treatment, and agricultural irrigation systems, reducing bushes facilitate efficient pipe size transitions while resisting corrosion and scaling that can reduce flow capacity over time . The compatibility with various joining methods allows integration with existing infrastructure without special adaptations, supporting system expansions and modifications with minimal downtime .

Product Detail

| Item Name |

CPVC Reducing Bush |

| Description |

Reducing Coupling/ Reducer/ Reducing Socket |

| Material |

100% Virgin CPVC |

| Key Word |

CPVC Pipe,CPVC Pipe Fittings, Reducer Coupling |

| Color |

Grey or Black or Blue |

| Connection |

Cement Type |

| Pressure |

PN10,PN16 |

| Standard |

BS EN ISO1452,ISO4422,DIN8063,GB/T1002.2 |

| Certification |

SGS,CE |

| Brand |

NULL/OEM |

It has following advantages:

The properties of the products

• Light weight:The weight per unit is only 1/6 of the cast-iron pipes, so the transport is quite convenient.

• High strength:The strength can get to 45mpa

• Low resistance:The internal surface of the pipe is smooth with no dirt and no blockage. The loss is 30% lower than that of the cast-iron pipes.

• Corrosion resistance:It has good quality of high acid resistance, alkali resistance, chemicals resistance and electrochemistry resistance, so the point of corrosion will not occur during the use.

• Easy installation:It adopts the glue and soft joining. Therefore, the installation is quite easy and sealing is reliable.

• Long service life:The service time can reach more than 50 years under the normal working pressure.

• Low cost:The cost of transport and installation is low, and the total engineering cost is 30-40% lower than of the cast-iron pipes.

• Non-toxic and sanitation:The product conforms to the standards of the drink water and water transported has no second pollution.

Technical Specifications

Table: Standard Reducing Bush Specifications

|

|

|

|

|

|

1/8″ to 4″ (DN6 to DN100) reduction

|

|

|

|

150 to 3000 PSI (class-dependent)

|

|

|

|

-20°C to 400°C (material-specific)

|

|

|

|

Carbon Steel, Stainless Steel, Brass, PVC, Alloys

|

|

|

|

Threaded (NPT, BSP), Socket Weld, Socket Fusion

|

|

|

|

ASME B16.9, ISO 4144, DIN 2605, MSS SP-43

|

International certifications

|

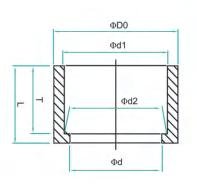

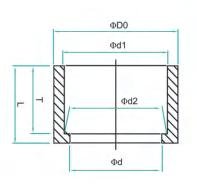

| Specification |

d0 |

d1 |

d2 |

T |

d |

L |

| DN20*15 |

25 |

20.30 |

20.10 |

17.00 |

16.00 |

18.50 |

| DN25*15 |

32 |

20.30 |

20.10 |

17.00 |

16.00 |

22.00 |

| DN25*20 |

32 |

25.30 |

25.10 |

19.50 |

21.00 |

22.00 |

| DN32*25 |

40 |

32.30 |

32.10 |

23.00 |

28.00 |

26.00 |

| DN40*20 |

50 |

25.30 |

25.10 |

19.50 |

21.00 |

31.00 |

| DN40*32 |

50 |

40.30 |

40.10 |

27.00 |

35.00 |

31.00 |

| DN50*20 |

63 |

25.30 |

25.10 |

23.00 |

21.00 |

37.50 |

| DN50*25 |

63 |

32.30 |

32.10 |

23.00 |

28.00 |

37.50 |

| DN50*40 |

63 |

50.30 |

50.10 |

32.00 |

45.00 |

37.50 |

| DN65*20 |

75 |

50.30 |

50.10 |

32.00 |

45.00 |

43.50 |

| DN65*25 |

75 |

63.30 |

63.10 |

38.50 |

56.00 |

43.50 |

| DN80*20 |

90 |

50.30 |

50.10 |

32.00 |

45.00 |

51.00 |

| DN80*25 |

90 |

63.30 |

63.10 |

38.50 |

56.00 |

51.00 |

| DN80*40 |

90 |

75.30 |

75.10 |

44.00 |

67.00 |

51.00 |

| DN100*20 |

110 |

63.30 |

63.10 |

38.50 |

56.00 |

61.00 |

| DN100*80 |

110 |

90.40 |

90.10 |

52.00 |

80.50 |

61.00 |

| DN125*100 |

140 |

110.40 |

110.10 |

62.00 |

101.50 |

76.20 |

| DN150*100 |

160 |

110.40 |

110.10 |

62.00 |

102.00 |

86.00 |

| DN150*125 |

160 |

140.40 |

140.00 |

77.00 |

134.00 |

86.00 |

| DN200*100 |

225 |

110.40 |

110.10 |

62.00 |

102.00 |

118.70 |

| DN200*150(φ225*160 |

225 |

160.40 |

160.00 |

86.00 |

151.00 |

118.70 |

| DN250*150 |

280 |

160.80 |

160.00 |

86.00 |

151.00 |

146.20 |

| DN250*200 |

280 |

225.80 |

225.00 |

119.50 |

218.00 |

146.20 |

| DN300*200 |

315 |

225.80 |

225.00 |

119.50 |

211.00 |

163.70 |

| DN300*250 |

315 |

281.50 |

280.00 |

146.20 |

263.50 |

163.70 |

| DN350*300 |

355 |

316.50 |

315.00 |

164.30 |

305.00 |

183.70 |

Frequently Asked Questions (FAQs)

Q1: What is the difference between concentric and eccentric reducing bushes?

Concentric reducing bushes feature a symmetrical design with a common centerline, creating a gradual transition ideal for vertical piping where fluid drainage isn’t a concern . Eccentric reducing bushes have offset centerlines to prevent air pocket formation in horizontal pipes, with the flat side positioned based on specific application requirements (top for air elimination, bottom for drainage) .

Q2: Can reducing bushes handle abrasive slurries and viscous fluids?

Yes, reducing bushes manufactured from abrasion-resistant materials like hardened steels or specialty alloys can handle abrasive slurries and viscous fluids effectively . The smooth interior transition minimizes turbulence that accelerates erosion, while proper material selection ensures compatibility with specific media characteristics and operating conditions .

Q3: What installation precautions are necessary for reducing bushes?

Proper installation requires clean, undamaged threads or proper weld preparation to ensure leak-free connections . For threaded versions, appropriate sealant (Teflon tape, pipe dope) should be applied to male threads only, avoiding contamination of the internal passage . Socket-weld bushes require proper gap spacing and welding procedures to prevent thermal distortion and ensure structural integrity .

Q4: How does a reducing bush differ from a conventional reducer?

Reducing bushes provide a more compact solution than conventional reducers, with a shorter length that saves space in constrained applications . While conventional reducers (concentric or eccentric) typically require more installation space, reducing bushes accomplish similar diameter transitions in approximately half the length, making them ideal for equipment connections and tight spaces .

Q5: What materials are suitable for high-temperature applications?

For temperatures exceeding 200°C, carbon steel (ASTM A105) and stainless steel (ASTM A182 F304/F316) are recommended, while specialty alloys like incoloy or inconel suit extreme temperatures above 400°C . Material selection should consider both temperature and pressure conditions, with appropriate derating factors applied for elevated temperature service .