Overview of Cross Pipe

Key Features of Cross Pipe

Multi-Directional Flow Distribution

Robust Construction and Material Versatility

Comprehensive Connection Options

Thermal Stress Management

Pressure-Rated Performance

Typical Applications of Cross Pipe

Industrial Process Piping

Fire Protection Systems

Plumbing and HVAC Systems

Irrigation and Agricultural Systems

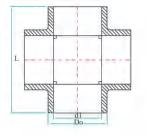

Technical Specifications

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SIZE | D0 | d1 | L |

| DN15 | 26.30 | 20.30 | 55.40 |

| DN20 | 31.90 | 25.30 | 65.40 |

| DN25 | 39.95 | 32.35 | 79.40 |

| DN32 | 49.80 | 40.40 | 95.40 |

| DN40 | 60.25 | 50.45 | 115.40 |

| DN50 | 75.90 | 63.50 | 141.40 |

| DN65 | 88.91 | 75.50 | 165.00 |

| DN80 | 105.15 | 90.55 | 195.00 |

| DN100 | 127.39 | 110.60 | 235.00 |

| DN125 | 161.40 | 140.60 | 296.00 |

| DN150 | 184.50 | 160.70 | 336.00 |

| DN200 | 253.80 | 226.20 | 465.00 |