Product Overview

Features of PPH Direct Coupling

Exceptional Chemical Resistance

Thermal Stability and Pressure Retention

Optimized Flow Characteristics

Fusion Welding Compatibility

Durability and Environmental Resistance

Material Advantages of PPH

Superior Crystalline Structure

Enhanced Mechanical Properties

Material Purity and Safety

Typical Applications of PPH Direct Coupling

Chemical Processing Systems

High-Purity Fluid Handling

Industrial Waste and Drainage Systems

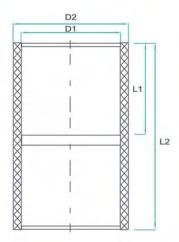

Technical Specifications

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SIZE | Number | D1 | D2 | L1 | L2 |

| DN15 | ZJ15 | 20.3 | 26.3 | 16.5 | 34.4 |

| DN20 | ZJ20 | 25.3 | 31.9 | 19 | 39 |

| DN25 | ZJ25 | 32.35 | 39.95 | 22.5 | 46.27 |

| DN32 | ZJ32 | 40.4 | 49.8 | 26.5 | 54.38 |

| DN40 | ZJ40 | 50.45 | 60.25 | 31.5 | 64.39 |

| DN50 | ZJ50 | 63.5 | 75.9 | 38 | 85.11 |

| DN65 | ZJ65 | 75.5 | 88.91 | 44 | 90.16 |

| DN80 | ZJ80 | 90.55 | 105.15 | 51.5 | 106.32 |

| DN100 | ZJ100 | 110.6 | 127.39 | 61.5 | 138.49 |

| DN125 | ZJ125 | 140.6 | 161.4 | 76 | 159.61 |

| DN150 | ZJ150 | 160.7 | 184.5 | 86.5 | 179.35 |

| dn200 | ZJ200 | 200 | 228.1 | 106.2 | 218 |

| DN200 | ZJ200 | 226.2 | 253.8 | 118.5 | 243.03 |

| dn250 | ZJ250 | 250 | 281.89 | 131.5 | 268 |

| DN250 | ZJ250 | 281.5 | 315.5 | 147 | 299 |

| DN300 | ZJ300 | 316.7 | 355 | 165 | 343 |

| DN350 | ZJ350 | 356.8 | 395 | 185 | 376 |

| DN400 | ZJ400 | 402 | 442 | 208 | 424 |

| DN250 (PN10) | ZJ250 | 280.6 | 306 | 147 | 299 |

| DN300 (PN10) | ZJ300 | 315.7 | 344 | 166 | 343 |

| DN350 (PN10) | ZJ350 | 355.8 | 385 | 183.5 | 373 |

| DN400 (PN10) | ZJ400 | 401 | 432 | 208 | 423 |