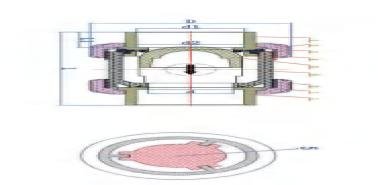

Overview of Double Union Check Valve

Key Features of Double Union Check Valve

-

Redundant Backflow Prevention The valve incorporates two independently operating check modules arranged in series, ensuring that if one mechanism fails due to debris or wear, the second mechanism activates to block reverse flow . This dual-seal design is certified for fluid category 3 protection (low-toxicity substances) and complies with industry standards for backflow prevention in potable water applications. -

Easy Maintenance with Union Connections Union ends on both sides allow quick disconnection of the valve without cutting pipes or disturbing adjacent piping . This design simplifies routine inspections, seal replacements, and cleaning, reducing system downtime by up to 50% compared to fixed-installation valves. -

Testable Design for Compliance Equipped with test cocks on both check modules, the valve enables in-line verification of sealing performance without removal . This feature is essential for annual compliance testing mandated by plumbing codes in commercial and municipal systems. -

Versatile Material Compatibility Constructed from corrosion-resistant materials like bronze for water services, stainless steel for chemicals, or PVC for cost-effective irrigation, the valve adapts to various media . Optional epoxy coatings or specialty seals (EPDM, Viton) extend suitability for aggressive fluids or extreme temperatures. -

Low Pressure Drop and High Flow Efficiency The full-bore design of check modules minimizes flow resistance, reducing energy consumption in pumping systems . This is critical in high-flow applications like fire sprinkler networks or water distribution, where pressure preservation is essential.

Typical Applications of Double Union Check Valve

-

Potable Water Systems: Installed at service connections to prevent backflow from commercial buildings or irrigation systems into municipal water mains . The redundant design meets code requirements for cross-connection control in low-hazard scenarios. -

Fire Protection Systems: Used in sprinkler and standpipe installations to avoid reverse flow of stagnant water into clean supply lines . The testable design allows annual verification required by insurance and safety standards. -

Industrial Processes: Protects cooling towers, boiler feed lines, and chemical injection points from contamination . Stainless steel or alloy versions resist corrosion from process media while union ends facilitate quick module replacement. -

Irrigation and Agricultural Systems: Prevents fertilizer or pesticide backflow into potable water sources, with PVC versions offering UV resistance and cost efficiency for outdoor use . The dual checks provide reliability in remote or automated watering systems.

Technical Specifications

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Number | Name | Material | Quantity | Unit |

| 1 | Socket/Socket End | UPVC/CPVCPPH | 2 | PCS |

| 2 | Nut | UPVC/CPVCPPH | 2 | PCS |

| 3 | Gasket | EPDMVTON | 1 | PCS |

| 4 | Spacer | UPVC/CPVCPPH | 1 | PCS |

| 5 | Ball | UPVC/CPVCPPH | 1 | PCS |

| 6 | O-Ring | EPDMVTON | 1 | PCS |

| SIZE | d | d1 | d2 | D | L | L1 | ||||||||

| UPvcCPvc | PPH | UPvcCPvc | PPH | |||||||||||

| ANSI | DIN | JIS | CNS | DIN | ANSI | DIN | JIS | CNS | DIN | |||||

| 1/2″(DN15) | 17.00 | 21.40 | 20.25 | 22.30 | 22.40 | 19.30 | 21.25 | 20.05 | 21.85 | 21.90 | 19.00 | 54.00 | 117.00 | 17.00 |

| 3/4″(DN20) | 22.00 | 26.75 | 25.25 | 26.30 | 26.40 | 24.10 | 26.58 | 25.05 | 25.85 | 25.90 | 23.80 | 63.00 | 135.00 | 19.50 |

| 1″(DN25) | 27.00 | 33.52 | 32.25 | 32.33 | 34.50 | 31.00 | 33.28 | 32.05 | 31.85 | 33.90 | 30.70 | 74.00 | 156.00 | 23.00 |

| 1-1/4″(DN32) | 34.00 | 42.28 | 40.25 | 38.43 | 42.50 | 39.00 | 42.05 | 40.05 | 37.85 | 41.90 | 38.60 | 85.00 | 178.00 | 27.00 |

| 1-1/2″(DN40) | 42.00 | 48.40 | 50.25 | 48.46 | 48.60 | 49.00 | 48.12 | 50.05 | 47.75 | 47.90 | 48.60 | 98.00 | 205.00 | 32.00 |

| 2″(DN50) | 52.00 | 60.45 | 63.25 | 80.56 | 60.60 | 61.90 | 60.18 | 63.05 | 59.75 | 59.90 | 61.40 | 118.00 | 236.00 | 38.50 |

| 2-1/2″(DN65) | 67.00 | 73.30 | 75.25 | 76.60 | 76.70 | 73.60 | 72.85 | 75.05 | 75.87 | 75.90 | 72.30 | 149.50 | 277.00 | 44.50 |

| 3″(DN80) | 82.00 | 89.25 | 90.35 | 89.60 | 89.70 | 88.30 | 88.70 | 90.05 | 88.83 | 88.90 | 86.90 | 72.00 | 319.00 | 52.00 |

| 4″(DN100) | 102.00 | 114.60 | 110.35 | 114.70 | 115.00 | 108.00 | 114.10 | 110.05 | 113.98 | 113.80 | 106.40 | 189.00 | 352.00 | 62.00 |