Overview of Female Thread Tee

Key Features of Female Thread Tee

Superior Corrosion Resistance

Robust Pressure Handling Capacity

Versatile Material Compatibility

Standardized Threading Options

Temperature Adaptability

Easy Installation and Maintenance

Typical Applications of Female Thread Tee

Industrial Plumbing Systems

Chemical Processing Plants

Fire Protection Systems

Hydraulic and Pneumatic Systems

Agricultural Irrigation

Oil and Gas Applications

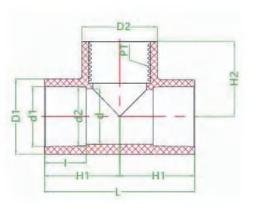

Technical Specifications

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SIZE | d1 | d2 | I | D1 | D2 | d | H1 | H2 | L | PT(牙) |

| DN15*1/2″ | 20.3 | 20.1 | 16 | 27 | 27 | 17 | 28.5 | 28.5 | 57 | 14 |

| DN20*3/4″ | 25.3 | 25.1 | 19 | 33 | 33 | 23 | 34 | 34 | 68 | 14 |

| DN25*1″ | 32.3 | 32.1 | 22 | 40.5 | 40.5 | 29 | 41.5 | 41.5 | 83 | 11 |

| DN32*1-1/4″ | 40.3 | 40.1 | 26 | 49.1 | 49.1 | 37 | 48.8 | 48.8 | 97.6 | 11 |

| DN40*1-1/2″ | 50.3 | 50.1 | 32 | 61 | 61 | 47 | 57.5 | 57.5 | 115 | 11 |

| DN50*2″ | 63.6 | 63.1 | 38 | 75 | 75 | 60 | 71.3 | 71.3 | 142.6 | 11 |