Overview of EPDM Flange Gasket

Key Features of EPDM Flange Gasket

1. Exceptional Chemical Resistance

2. Excellent Weathering and Temperature Resistance

3. Durability and Flexibility

4. Hygienic and Regulatory Compliance

Typical Applications of EPDM Flange Gasket

Water Supply and Treatment Systems

Chemical and Industrial Processing

Food and Pharmaceutical Industries

Heating, Ventilation, and Steam Applications

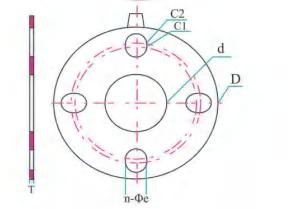

Technical Specifications

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SIZE | Number | D1 | D2 | D3 | L1 | n–φe |

| DN15 | FLD15 | 95 | 56 | 17 | 3 | 4-φ18 |

| DN20 | FLD20 | 105 | 75 | 20 | 3 | 4-φ18 |

| DN25 | FLD25 | 115 | 85 | 26 | 3 | 4-φ18 |

| DN32 | FLD32 | 140 | 100 | 34 | 3 | 4-φ18 |

| DN40 | FLD40 | 150 | 110 | 44 | 3 | 4-φ18 |

| DN50 | FLD50 | 165 | 125 | 55 | 3 | 4-φ18 |

| DN65 | FLD65 | 185 | 145 | 68 | 3 | 4-φ18 |

| DN80 | FLD80 | 200 | 160 | 76 | 4 | 8-φ18 |

| DN100 | FLD100 | 220 | 180 | 97 | 4 | 8-φ18 |

| DN125 | FLD125 | 250 | 210 | 130 | 4 | 8-φ18 |

| DN150 | FLD150 | 285 | 240 | 150 | 4.5 | 8-φ22 |

| DN200 | FLD200 | 340 | 295 | 210 | 4.5 | 8-φ22 |

| DN250 | FLD250 | 405 | 355 | 260 | 4.5 | 12-φ26 |

| DN300 | FLD300 | 445 | 400 | 310 | 4.5 | 12-φ26 |

| DN350 | FLD350 | 510 | 460 | 360 | 4.5 | 16-φ26 |

| DN400 | FLD400 | 570 | 515 | 400 | 4.5 | 16-φ26 |