Overview of Handle Butterfly Valve

Key Features of Handle Butterfly Valve

-

Compact and Lightweight Design Handle butterfly valves feature a slim profile and low weight (up to 50% lighter than gate or globe valves), reducing structural support needs and simplifying installation in tight spaces . The unitary body construction minimizes part count, enhancing durability while lowering overall costs . -

Quick Quarter-Turn Operation The handle enables 90-degree rotation for full open/close cycles, allowing swift flow control within seconds . This rapid action is critical in emergency shut-off scenarios or processes requiring frequent adjustments . -

Low Pressure Drop and High Flow Efficiency When fully open, the disc’s thin profile presents minimal flow obstruction, resulting in a low-pressure drop and energy savings . The streamlined flow path minimizes turbulence, making these valves ideal for high-volume applications like water distribution or HVAC systems . -

Bubble-Tight Sealing Equipped with resilient seats (EPDM, NBR, PTFE), the valve achieves bubble-tight shut-off in both directions, preventing leakage in closed positions . The seal design compensates for wear and minor misalignments, extending service life . -

Versatile Material Compatibility Available in corrosion-resistant materials like stainless steel 316 for aggressive media or coated cast iron for water services, the valves adapt to various fluids—water, chemicals, gases, and slurries . Material selections ensure compliance with hygienic standards (e.g., 3A) for food, pharmaceutical, or sanitary applications . -

Easy Maintenance and Long Service Life The simple design requires minimal upkeep, with replaceable seats and stems accessible without removing the valve body . Robust construction ensures over 100,000 cycles under standard conditions, with some models exceeding 50 years of service .

Typical Applications of Handle Butterfly Valve

-

Water and Wastewater Treatment: Used in pumping stations, distribution mains, and treatment plants for isolation and flow control, leveraging corrosion resistance and tight sealing for potable or wastewater . -

HVAC Systems: Regulate chilled or hot water flow in heating/cooling circuits, ensuring energy-efficient temperature control in commercial buildings . -

Fire Protection Systems: Grooved-type valves enable quick installation in sprinkler networks, providing reliable shut-off during emergencies . -

Chemical and Industrial Processing: Handle acids, alkalis, and solvents in pipelines, with material options like SS316 resisting corrosion . -

Food and Beverage Industry: Sanitary designs with polished surfaces and CIP compatibility meet hygiene standards for dairy, beverages, and pharmaceuticals .

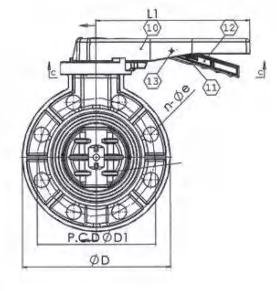

Technical Specifications

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

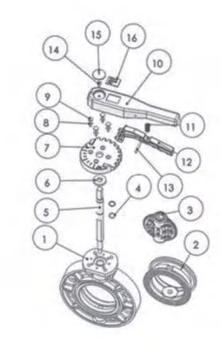

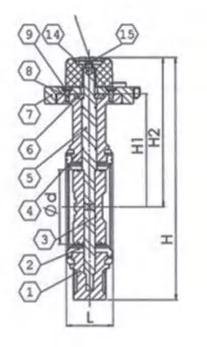

| Number | Name | Material | Quantity |

| 01 | BODY | PVC,CPVC,FRPP,PP | 1 |

| 02 | SEAT SEAL | EPDM,FPM | 1 |

| 03 | DISC | PVC,CPVC,FRPP,PP | 1 |

| 04 | O-RING | EPDM,FPM | 2 |

| 05 | STEM Rod/Bar | STEEL,304,316 | 1 |

| 06 | BEAR | ABS | 1 |

| 07 | PLATE | PVC | 1 |

| 08 | SCREW | STEEL | 4 |

| 09 | CAPScrew | PVC | 4 |

| 10 | HANDLE | ABS | 1 |

| 11 | SPRING | 304 | 1 |

| 12 | LEVER | ABS | 1 |

| 13 | SET PIN | 304 | 1 |

| 14 | BOLT | STEEL | 1 |

| 15 | LOGO | ABS | 1 |

| 16 | MARK Specification | ABS | 1 |