Overview of Iso-Cross Tube

Key Features of Iso-Cross Tube

-

High Strength-to-Weight Ratio The triangular grid configuration maximizes load-bearing capacity while reducing weight by 30–50% compared to solid or conventional tubular structures . This design efficiently distributes axial, torsional, and bending stresses, preventing localized failures in demanding environments such as aerospace frame assemblies or automotive chassis reinforcements . -

Customizable Geometry and Materials Iso-Cross Tubes can be fabricated with variable node spacing, wall thickness, and fiber orientation to match specific mechanical requirements . Materials range from carbon fiber for maximum strength and corrosion resistance to fiberglass for cost-sensitive applications, with optional coatings (e.g., epoxy, polyurethane) for enhanced UV or chemical resistance . -

Vibration Damping and Fatigue Resistance The repetitive triangular cells dissipate energy from vibrations and cyclic loads, reducing stress concentration and extending service life in dynamic systems like wind turbine blades or machinery linkages . Fatigue testing shows a 60% higher cycle tolerance versus solid tubes under equivalent loads . -

Thermal and Electrical Insulation Composite materials provide low thermal conductivity (0.5–5 W/m·K) and electrical non-conductivity, making these tubes suitable for insulating components in electronic enclosures, power transmission systems, or HVAC ducting . -

Eco-Efficient Manufacturing The open-web structure requires less raw material, reducing production waste and life-cycle carbon footprint . Automated filament winding or braiding processes enable high precision and repeatability for large-scale orders .

Typical Applications

-

Aerospace and UAVs: Fuselage trusses and wing spars requiring lightweight rigidity and resistance to aerodynamic forces . -

Robotics and Automation: Articulated arms and conveyor guides where low inertia and high precision are critical . -

Sports Equipment: Bicycle frames and archery bows leveraging enhanced energy return and impact absorption . -

Industrial Scaffolding: Modular platforms offering quick assembly and corrosion resistance in harsh plants .

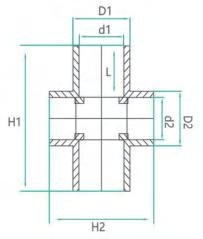

Technical Specifications

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SIZE | Number | D1 | d1 | D2 | d2 | L | I | H1 | H2 |

| DN80x40 | YS80x40 | 105.15 | 90.55 | 60.25 | 50.45 | 51.5 | 31.5 | 154.6 | 154.5 |

| DN80x50 | YS80x50 | 105.15 | 90.55 | 75.9 | 43.5 | 51.5 | 38 | 166.8 | 167 |

| DN100x40 | YS100x40 | 127.39 | 110.6 | 60.25 | 50.45 | 61.5 | 31.5 | 174 | 174 |

| DN100x50 | YS100x50 | 127.39 | 110.6 | 75.9 | 63.5 | 61.5 | 38 | 186.8 | 187 |

| DN125x40 | YS125x40 | 161.4 | 140.6 | 60.25 | 50.45 | 76 | 31.5 | 205 | 204.9 |

| DN125x50 | YS125x50 | 161.4 | 140.6 | 75.9 | 63.5 | 76 | 38 | 218 | 218 |

| DN125x65 | YS125x65 | 161.4 | 140.6 | 88.91 | 75.5 | 76 | 44 | 230 | 230 |

| DN150x50 | YS150x50 | 184.5 | 160.7 | 75.9 | 63.5 | 86.5 | 38 | 238.6 | 238.8 |

| DN150x100 | YS150x100 | 184.5 | 160.7 | 127.39 | 110.6 | 86.5 | 61.5 | 285.8 | 286 |