Overview of One-Piece Flange

Key Features of One-Piece Flange

-

Integrated Clamping Design The One-Piece Flange features a unibody construction that merges the flange ring with a clamping collar, ensuring even pressure distribution and eliminating joint failures common in multi-component flanges. This design enhances sealing reliability under pressure fluctuations and mechanical stress . -

High-Pressure and Temperature Resilience Engineered for extreme operating conditions, these flanges withstand pressures up to 35 MPa (350 bar) and temperatures from -50°C to 400°C. Materials like ASTM A105 carbon steel and ASTM A182 stainless steel provide exceptional tensile strength and corrosion resistance, suitable for hydraulic systems and aggressive media . -

Leak-Free Performance The one-piece structure prevents leakage at seam points, with precision-machined sealing surfaces (e.g., raised face or ring-type joint) ensuring tight gasket compression. This is critical in high-stakes applications like oil and gas pipelines or chemical transport . -

Easy Installation and Maintenance With fewer components than split flanges, installation requires minimal effort. The design allows quick alignment and securing with metric or inch screws, reducing assembly time by up to 30% compared to traditional flanges . -

Vibration and Fatigue Resistance The monolithic construction dampens vibrations and withstands cyclic loading, making these flanges ideal for dynamic environments like industrial machinery or mobile hydraulic equipment .

Typical Applications of One-Piece Flange

-

Hydraulic Power Systems: Used in high-pressure hydraulic lines for construction machinery, agricultural equipment, and industrial presses, where leak-free connections are critical . -

Oil and Gas Pipelines: Employed in upstream and midstream operations to connect valves, pumps, and compressors, resisting sour gas corrosion and pressure surges . -

Chemical Processing Plants: Ideal for handling corrosive fluids like acids and solvents, with stainless steel variants preventing chemical degradation . -

Power Generation Systems: Secure connections in steam, coolant, and fuel lines within turbines and boilers, ensuring safety under thermal cycling . -

Marine and Offshore Applications: Certified for use in shipbuilding and offshore platforms, with materials resistant to saltwater corrosion .

Technical Specifications

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

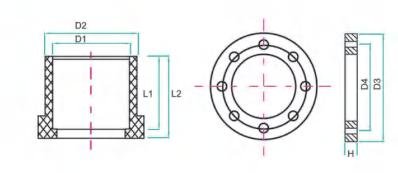

| SIZE | Number | D1 | D2 | H | L1 | L2 | D3 | r-φ-e | D4/BCD |

| DN15 | HFL15 | 20.3 | 26.3 | 13.1 | 16.5 | 25 | 95 | 4-φ-18 | 65 |

| DN20 | HFL20 | 25.3 | 31.9 | 14.7 | 19 | 28.5 | 105 | 4-φ-18 | 75 |

| DN25 | HFL25 | 32.35 | 39.95 | 16 | 22.5 | 31.5 | 115 | 4-φ-18 | 85 |

| DN32 | HFL32 | 40.4 | 49.8 | 17.5 | 26.5 | 34 | 140 | 4-φ-18 | 100 |

| DN40 | HFL40 | 50.45 | 60.25 | 18.6 | 31.5 | 38.5 | 150 | 4-φ-18 | 110 |

| DN50 | HFL50 | 63.5 | 75.9 | 20.3 | 38 | 45 | 165 | 4-φ-18 | 125 |

| DN65 | HFL65 | 75.5 | 88.91 | 23.6 | 44 | 51.5 | 185 | 4-φ-18 | 145 |

| DN80 | HFL80 | 90.55 | 105.15 | 26.3 | 51.5 | 60 | 200 | 8-φ-18 | 160 |

| DN100 | HFL100 | 110.6 | 127.39 | 28 | 61.5 | 70.7 | 220 | 8-φ-18 | 180 |

| DN125 | HFL125 | 140.6 | 161.4 | 33.2 | 76 | 86 | 250 | 8-φ-18 | 210 |

| DN150 | HFL150 | 160.7 | 184.5 | 34.1 | 86.5 | 95 | 285 | 8-φ-22 | 240 |

| dn200 | HFL200 | 200 | 340 | 36 | 106.2 | 113 | 340 | 8-φ-22 | 295 |

| DN200 | hf1250 | 226.2 | 253.8 | 35 | 118.5 | 130 | 340 | 8-φ-22 | 295 |

| dn250 | HFL250 | 250 | 395 | 40 | 131.5 | 138.5 | 395 | 12-φ-22 | 350 |

| DN250 | HFL250 | 281.5 | 314.8 | 41.4 | 147 | 165 | 405 | 12-φ-26 | 355 |

| DN300 | HFL300 | 316.7 | 344.5 | 41.7 | 165 | 188 | 445 | 12-φ-26 | 400 |

| DN350 | HFL350 | 356.8 | 386.2 | 45 | 183.5 | 193.5 | 510 | 16-φ-26 | 445-460 |

| DN400 | HFL400 | 402 | 432.7 | 47 | 208 | 231 | 572 | 16-φ-26 | 495-515 |

| DN250 (PH10) | HFL250 | 280.6 | 304.7 | 41.4 | 147 | 165 | 405 | 16-φ-26 | 355 |

| DN300 (PH10) | HFL300 | 315.7 | 341.5 | 41.7 | 165 | 188 | 445 | 16-φ-26 | 400 |

| DN350 (PH10) | HFL350 | 355.8 | 385 | 45 | 183.5 | 193.5 | 510 | 16-φ-26 | 460 |

| DN400 (PH10) | HFL400 | 401 | 429.5 | 46 | 208 | 231 | 570 | 16-φ-26 | 515 |