Overview of Pipe Blockage Challenges

Key Features of Professional Pipe Blockage Solutions

Advanced Mechanical Augering Systems

High-Pressure Water Jetting Technology

Pneumatic Drain Blasters

Chemical and Enzymatic Treatments

Pipeline Assessment and Diagnostics

Typical Applications of Pipe Blockage Solutions

Municipal Sewer and Drainage Systems

Industrial Processing Pipelines

Residential Plumbing Networks

Food Service and Hospitality Industries

Emergency Response and Disaster Recovery

Technical Specifications

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

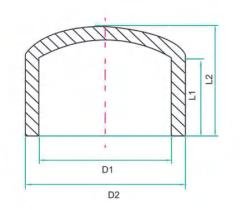

| SIZE | Number | D1 | D2 | L1 | L2 |

| DN15 | GD15 | 20.3 | 26.3 | 16.5 | 21.81 |

| DN20 | GD20 | 25.3 | 31.9 | 19 | 25.68 |

| DN25 | GD25 | 32.35 | 39.95 | 22.5 | 30.62 |

| DN32 | GD32 | 40.4 | 49.8 | 26.5 | 36.81 |

| DN40 | GD40 | 50.45 | 60.25 | 31.5 | 44.68 |

| DN50 | GD50 | 63.5 | 75.9 | 38 | 53.81 |

| DN65 | GD65 | 75.5 | 88.91 | 44 | 62.44 |

| DN80 | GD80 | 90.55 | 105.15 | 51.5 | 73.11 |

| DN100 | GD100 | 110.6 | 127.39 | 61.5 | 84.27 |

| DN125 | GD125 | 140.6 | 161.4 | 76 | 110.06 |

| DN150 | GD150 | 160.7 | 184.5 | 86.5 | 125.9 |

| dn200 | GD200 | 200 | 228.1 | 107.37 | 147 |

| DN200 | GD200 | 226.2 | 253.8 | 118.5 | 170.58 |

| dn250 | GD250 | 250 | 283.4 | 131.5 | 180 |

| DN250 | GD250 | 281.5 | 314.8 | 147 | 213 |

| DN300 | GD300 | 316.7 | 344.5 | 165 | 216 |

| DN350 | GD350 | 356.8 | 395 | 185 | 252 |

| DN400 | GD400 | 402 | 442 | 208 | 285 |

| DN350 (PN10) | GD350 | 356.8 | 386.2 | 183.5 | 255 |

| DN400 (PN10) | GD400 | 402 | 432.7 | 208 | 296 |