Overview of Reducing Tee

Key Features of Reducing Tee

Optimized Flow Distribution

Robust Construction and Material Versatility

Pressure and Temperature Resilience

Installation Flexibility and Compatibility

Corrosion and Abrasion Resistance

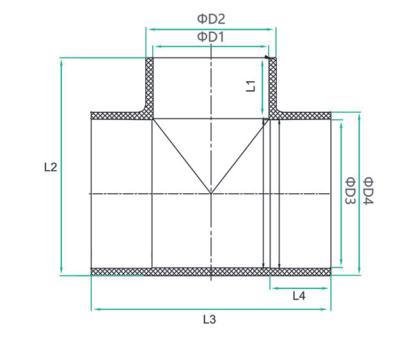

Technical Specifications

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Typical Applications of Reducing Tee

Chemical and Process Industries

Water and Wastewater Treatment

Oil and Gas Pipeline Systems

Power Generation and HVAC Systems

Mining and Industrial Applications

| SIZE | NO. | D1 | D2 | L1 | L2 | L3 | D3 | D4 | L4 |

| DN25x15 | Y3T25x15 | 20.3 | 26.3 | 16.5 | 53.7 | 68 | 32.25 | 39.95 | 22.5 |

| DN25x20 | Y3T25x20 | 25.3 | 31.9 | 17 | 64.3 | 81 | 40.5 | 47.5 | 26.5 |

| DN25x25 | Y3T25x25 | 25.3 | 31.9 | 17 | 74.4 | 91 | 50.45 | 57.5 | 31.5 |

| DN30x25 | Y3T30x25 | 32.5 | 38.5 | 22.5 | 58 | 98 | 50.45 | 50.25 | 31.5 |

| DN30x25 | Y3T50x25 | 32.5 | 39.95 | 22.5 | 93 | 111 | 63.5 | 75.9 | 38 |

| DN30x32 | Y3T50x32 | 40.4 | 49.8 | 26.5 | 97 | 119 | 63.5 | 75.9 | 38 |

| DN35x25 | Y3T65x25 | 32.5 | 39.95 | 22.5 | 105.6 | 123 | 75.5 | 88.91 | 44 |

| DN35x40 | Y3T65x40 | 50.45 | 60.25 | 31.5 | 115 | 141 | 75.5 | 88.91 | 44 |

| DN80x25 | Y3T80x25 | 32.5 | 39.95 | 22.5 | 120.8 | 137.9 | 90.55 | 105.15 | 51.5 |

| DN80x40 | Y3T80x40 | 50.45 | 60.25 | 31.5 | 130.5 | 156 | 90.55 | 105.15 | 51.5 |

| DN80x50 | Y3T80x50 | 63.5 | 75.9 | 38 | 137 | 169 | 90.55 | 105.15 | 31.5 |

| DN100x25 | Y3T100x25 | 32.5 | 39.95 | 22.5 | 142.6 | 158 | 110.6 | 127.39 | 61.5 |

| DN100x50 | Y3T100x50 | 63.5 | 75.9 | 38 | 156 | 189 | 110.6 | 127.39 | 61.5 |

| DN100x65 | Y3T100x65 | 75.5 | 88.91 | 34 | 164.2 | 200.96 | 110.6 | 127.39 | 61.5 |

| DN125x25 | Y3T125x25 | 32.5 | 39.95 | 22.5 | 180 | 197 | 120.6 | 140.3 | 76 |

| DN125x50 | Y3T125x50 | 90.55 | 106.15 | 51.5 | 203.8 | 246 | 140 | 161.4 | 76 |

| DN150x50 | Y3T150x50 | 63.5 | 75.9 | 38 | 211.5 | 240.5 | 140.7 | 184.5 | 86.5 |

| DN150x100 | Y3T125x100 | 110.6 | 127.39 | 61.5 | 234.3 | 287.5 | 160.7 | 184.5 | 86.5 |

| dn200x110 | Y3T200x110 | 110 | 127.5 | 61.5 | 277.5 | 356 | 201.1 | 228.1 | 106.2 |

| dn200x160 | Y3T200x160 | 160 | 184.9 | 86.5 | 302.35 | 376 | 200 | 228.1 | 106.2 |

| DN200x100 | Y3T200x100 | 110.6 | 127.39 | 61.5 | 302.3 | 352 | 226.2 | 253.8 | 118.5 |

| DN200x150 | Y3T200x150 | 160.7 | 184.5 | 86.5 | 327.2 | 401.5 | 226.2 | 253.8 | 118.5 |

| dn250x110 | Y3T250x110 | 110 | 127.5 | 61.5 | 330.5 | 429 | 250 | 283.4 | 131.5 |

| dn250x160 | Y3T250x160 | 160 | 184.9 | 86.5 | 355.2 | 429 | 250 | 283.4 | 131.5 |

| DN300x100 | Y3T300x100 | 226.2 | 253.8 | 120 | 442 | 525 | 287.5 | 315.3 | 147 |

| DN300x200 | Y3T300x200 | 226.2 | 253.8 | 120 | 440 | 564 | 317.5 | 355 | 147 |

| DN300x150 | Y3T300x150 | 160.8 | 185 | 87 | 427 | 564 | 317.5 | 355 | 165 |

| DN350x300 | Y3T350x300 | 316.7 | 355 | 165 | 546 | 696 | 356.8 | 395 | 185 |

| DN350x200 | Y3T350x200 | 226.2 | 253.8 | 120 | 501 | 696 | 356.8 | 395 | 185 |

| DN400x300 | Y3T400x300 | 316.7 | 355 | 165 | 593 | 740 | 402 | 442 | 208 |

| DN400x200 | Y3T400x200 | 226.2 | 253.8 | 120 | 548 | 740 | 402 | 442 | 208 |