Product Overview

Features of UPVC Reducing Tee

-

Superior Corrosion & Chemical Resistance – Highly resistant to acids, alkalis, and a wide range of corrosive chemicals, making it ideal for industrial effluent, chemical transport, and agricultural applications involving fertilizers . -

Optimized Flow with Reduction Design – Features a smooth interior surface and a precision reduction in the branch outlet, which minimizes friction loss, prevents sediment buildup, and ensures efficient flow transition between different pipe diameters . -

Lightweight and Easy Installation – Significantly lighter than metal tees, reducing transportation and labor costs. Allows for quick and secure connections via solvent cement welding or threaded ends, simplifying the installation process . -

Robust Construction & Long Service Life – Designed to withstand pressure ratings of PN10 and PN16 (1.0-1.6 MPa) and temperatures ranging from 0°C to 60°C (with some SCH80 ratings up to 65°C), ensuring a service life of over 50 years . -

Eco-Friendly and Non-Toxic – Complies with international potable water safety standards (e.g., NSF/ANSI, ISO 4422), ensuring safe use in drinking water systems without affecting water quality . -

Versatile Connection Types – Available in various types including solvent weld, threaded (male/female), and rubber ring (gasketed) ends to suit different installation requirements and pipeline designs .

Typical Uses of UPVC Reducing Tee

-

Potable Water Distribution Systems: Used to branch off a smaller water supply line to a building or fixture from a larger main distribution pipe. Its non-toxic nature ensures the water remains safe and uncontaminated . -

Industrial Chemical Processing: Ideal for plants handling corrosive chemicals, acids, or alkalis due to its exceptional chemical resistance. Used to divert process streams to equipment with different inlet sizes . -

Agricultural Irrigation Networks: Effectively distributes water from a large main line to smaller feeder lines or drip irrigation systems. Its resistance to corrosion from fertilizers and insecticides makes it a durable choice for farming . -

Sewage and Drainage Systems: Employed in sewer and waste drainage networks to connect pipes of varying diameters, efficiently managing the flow of waste and corrosive gases in residential, commercial, and industrial settings . -

Mining and Ventilation Systems: Well-suited for draining corrosive liquids in mines and for ventilation ducts, as they are easy to install in hard-to-reach places and resist chemical degradation . -

Electrical Conduit Systems: Serves as a protective, non-conductive fitting for electrical and telecommunications cables, allowing for directional changes and size adaptations in conduit runs .

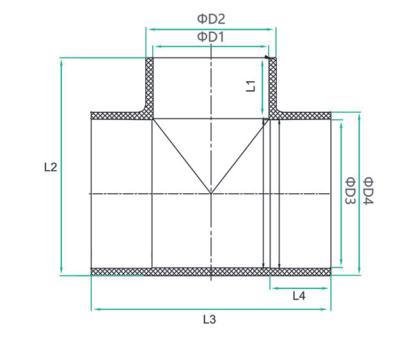

Range of Production

|

SIZE |

NO. | D1 | D2 | L1 | L2 | L3 | D3 | D4 | L4 |

| DN25x15 | Y3T25x15 | 20.3 | 26.3 | 16.5 | 53.7 | 68 | 32.25 | 39.95 |

22.5 |

|

DN25x20 |

Y3T25x20 | 25.3 | 31.9 | 17 | 64.3 | 81 | 40.5 | 47.5 | 26.5 |

| DN25x25 | Y3T25x25 | 25.3 | 31.9 | 17 | 74.4 | 91 | 50.45 | 57.5 |

31.5 |

|

DN30x25 |

Y3T30x25 | 32.5 | 38.5 | 22.5 | 58 | 98 | 50.45 | 50.25 | 31.5 |

| DN30x25 | Y3T50x25 | 32.5 | 39.95 | 22.5 | 93 | 111 | 63.5 | 75.9 |

38 |

|

DN30x32 |

Y3T50x32 | 40.4 | 49.8 | 26.5 | 97 | 119 | 63.5 | 75.9 | 38 |

| DN35x25 | Y3T65x25 | 32.5 | 39.95 | 22.5 | 105.6 | 123 | 75.5 | 88.91 |

44 |

|

DN35x40 |

Y3T65x40 | 50.45 | 60.25 | 31.5 | 115 | 141 | 75.5 | 88.91 | 44 |

| DN80x25 | Y3T80x25 | 32.5 | 39.95 | 22.5 | 120.8 | 137.9 | 90.55 | 105.15 |

51.5 |

|

DN80x40 |

Y3T80x40 | 50.45 | 60.25 | 31.5 | 130.5 | 156 | 90.55 | 105.15 | 51.5 |

| DN80x50 | Y3T80x50 | 63.5 | 75.9 | 38 | 137 | 169 | 90.55 | 105.15 |

31.5 |

|

DN100x25 |

Y3T100x25 | 32.5 | 39.95 | 22.5 | 142.6 | 158 | 110.6 | 127.39 | 61.5 |

| DN100x50 | Y3T100x50 | 63.5 | 75.9 | 38 | 156 | 189 | 110.6 | 127.39 |

61.5 |

|

DN100x65 |

Y3T100x65 | 75.5 | 88.91 | 34 | 164.2 | 200.96 | 110.6 | 127.39 | 61.5 |

| DN125x25 | Y3T125x25 | 32.5 | 39.95 | 22.5 | 180 | 197 | 120.6 | 140.3 |

76 |

|

DN125x50 |

Y3T125x50 | 90.55 | 106.15 | 51.5 | 203.8 | 246 | 140 | 161.4 | 76 |

| DN150x50 | Y3T150x50 | 63.5 | 75.9 | 38 | 211.5 | 240.5 | 140.7 | 184.5 |

86.5 |

|

DN150x100 |

Y3T125x100 | 110.6 | 127.39 | 61.5 | 234.3 | 287.5 | 160.7 | 184.5 | 86.5 |

| dn200x110 | Y3T200x110 | 110 | 127.5 | 61.5 | 277.5 | 356 | 201.1 | 228.1 |

106.2 |

|

dn200x160 |

Y3T200x160 | 160 | 184.9 | 86.5 | 302.35 | 376 | 200 | 228.1 | 106.2 |

| DN200x100 | Y3T200x100 | 110.6 | 127.39 | 61.5 | 302.3 | 352 | 226.2 | 253.8 |

118.5 |

|

DN200x150 |

Y3T200x150 | 160.7 | 184.5 | 86.5 | 327.2 | 401.5 | 226.2 | 253.8 | 118.5 |

| dn250x110 | Y3T250x110 | 110 | 127.5 | 61.5 | 330.5 | 429 | 250 | 283.4 |

131.5 |

|

dn250x160 |

Y3T250x160 | 160 | 184.9 | 86.5 | 355.2 | 429 | 250 | 283.4 | 131.5 |

| DN300x100 | Y3T300x100 | 226.2 | 253.8 | 120 | 442 | 525 | 287.5 | 315.3 |

147 |

|

DN300x200 |

Y3T300x200 | 226.2 | 253.8 | 120 | 440 | 564 | 317.5 | 355 | 147 |

| DN300x150 | Y3T300x150 | 160.8 | 185 | 87 | 427 | 564 | 317.5 | 355 |

165 |

|

DN350x300 |

Y3T350x300 | 316.7 | 355 | 165 | 546 | 696 | 356.8 | 395 | 185 |

| DN350x200 | Y3T350x200 | 226.2 | 253.8 | 120 | 501 | 696 | 356.8 | 395 |

185 |

|

DN400x300 |

Y3T400x300 | 316.7 | 355 | 165 | 593 | 740 | 402 | 442 | 208 |

|

DN400x200 |

Y3T400x200 | 226.2 | 253.8 | 120 | 548 | 740 | 402 | 442 | 208 |