Overview of Saddle Joint

Key Features of Saddle Joint

1. Leak-Proof Sealing Mechanism

2. Hot-Tap Capability

3. Corrosion and Chemical Resistance

4. Versatile Installation Options

5. Full-Flow Design

Typical Applications of Saddle Joint

Water Supply Systems

Industrial Process Piping

Irrigation and Agriculture

Mining and Dewatering

Pipeline Modifications and Repairs

Technical Specifications

|

|

|

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

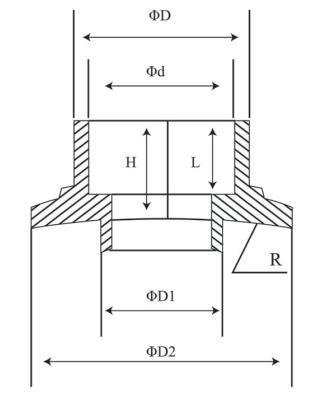

| 公称尺寸φ | φ0 | φd | φ D1 | φ D2 | R | H | L |

| φ75/32 | 40 | 32 | 35 | 70 | 37.5 | 36 | 25 |

| φ90/32 | 40 | 32 | 28 | 60 | 45 | 26 | 22 |

| φ90/50 | 60 | 50 | 55 | 85 | 45 | 43 | 31 |

| φ110/32 | 40 | 32 | 29 | 60 | 55 | 26 | 22 |

| φ110/50 | 60 | 50 | 55 | 100 | 55 | 45 | 31 |

| φ110/63 | 72 | 63 | 60 | 100 | 55 | 42 | 37 |

| φ140/32 | 40 | 32 | 29 | 60 | 70 | 26 | 22 |

| φ140/50 | 60 | 50 | 55 | 100 | 70 | 45 | 41 |

| φ140/63 | 72 | 63 | 55 | 100 | 70 | 42 | 37 |

| φ160/32 | 40 | 32 | 29 | 60 | 80 | 26 | 22 |

| φ160/50 | 60 | 50 | 55 | 100 | 80 | 45 | 31 |

| φ160/63 | 72 | 63 | 55 | 100 | 80 | 42 | 38 |

| φ250/32 | 40 | 32 | 29 | 60 | 112.5 | 26 | 22 |

| φ250/50 | 60 | 50 | 55 | 100 | 112.5 | 45 | 31 |

| φ250/63 | 72 | 63 | 40 | 100 | 112.5 | 42 | 37 |

| φ325/50 | 86 | 76 | 70 | 115 | 112.5 | 42 | 38 |

| φ325/90 | 104 | 90 | 90 | 170 | 112.5 | 70 | 51 |

| φ350/63 | 72 | 63 | 60 | 100 | 125 | 42 | 37 |

| φ350/75 | 86 | 75 | 70 | 115 | 125 | 42 | 38 |

| φ380/32 | 40 | 32 | 29 | 60 | 140 | 26 | 22 |

| φ380/50 | 60 | 50 | 55 | 100 | 140 | 45 | 31 |

| φ380/63 | 72 | 63 | 60 | 100 | 140 | 42 | 37 |

| φ280/75 | 86 | 75 | 70 | 115 | 140 | 42 | 38 |

| φ315/32 | 40 | 32 | 29 | 60 | 157.5 | 26 | 22 |

| φ315/50 | 60 | 50 | 55 | 100 | 157.5 | 45 | 31 |

| φ315/63 | 74 | 63 | 60 | 100 | 157.5 | 42 | 37 |

| φ315/75 | 86 | 75 | 70 | 115 | 157.5 | 42 | 38 |

| φ315/90 | 104 | 90 | 90 | 170 | 157.5 | 74 | 51 |